The following mechanical safety devices have been applied:

1. bowl lid transparent plastic.

The following electrical safety devices have been applied:

1. start up with start/stop button that must be pressed again to restart the machine after an outage of

power main;

2. microswitch on the head as preventing machine startup when the high head.

INSTALLATION AND FUNCTIONING TESTS

Open the carton and make sure that all components are intact.

Place the machine on a suitably plane, smooth and dry surface sufficiently strong to support the machine

weight.

Install near an outlet complying to EU and derived from an electrical system made to current regulations.

Before completing the connections, check that the mains correspond to the data shown on the plate.

AVAILABLE CONTROLS (Fig. 2) AND MACHINE USE

1. STOP BUTTON(rif.8 fig.2): press the button to stop the operation of the machine;

2. START BUTTON(rif.8 fig.2): press the button to start the machine; the startup is enabled only when

the head down;

3. KNOB SPEED CHANGE(rif.7 fig.2): allows to adjust the speed of rotation of the tool as a function of

the processing to be performed (continuous adjustment from minimum to maximum speed);

4. LEVER HEAD LIFT(rif.4 fig.2): allows you to unlock and lock the head to raise or lower the head.

PLACEMENT BOWL AND TOOL

1. Raise the head by turning the lever side.

2. Place the bowl in seat and turn it clockwise to lock it.

3. Insert the tool on the shaft. Then lock it by rotating it counter-clockwise.

4. Lower the head by turning the lever side.

MACHINE USE

1. Select a speed with the knob in function of the type of processing: for hard dough select a low speed

(1), for soft dough select a high speed (2 or 3).

2. Start the machine by pressing the START button.

3. At the end of the process to stop the machine by pressing the STOP button.

4. Turn the lever side to raise the head, release it to discharge the product worked.

5. After processing, rinse the tank and the tool with warm water and detergent.

6. Clean the lid with a damp sponge.

CLEANING THE MACHINE

The machine must be carefully cleaned at least once a day or more often as necessary.

To clean the machine use only a cloth soaked in water and non-lathery detergent for dishes with pH at 7-8

and at least at + 30° C. Do not use steel wool or abrasive cleaning products.

TROUBLESHOOTING

In the event of breakdowns or malfunctioning, turn off the main wall switch and contact your local Dealer

’s

After-sales service. Do not disassemble any internal machine parts.

The Manufacturer declines all responsability for any tampering!

LONG PERIODS OF INACTIVITY

If the machine is to be left idle for long periods of time, turn off the main wall switch, thoroughly clean the

machine and cover it with a sheet to protect it from dust.

6

Summary of Contents for AP5

Page 15: ...FIGURE PICTURE ILLUSTRATION BILDER Fig 1 Abb 1 Fig 2 Abb 2 15...

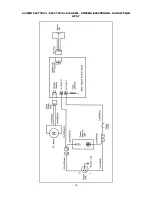

Page 16: ...SCHEMI ELETTRICI ELECTRICAL DIAGRAM SCH MA LECTRIQUE SCHALTPLAN AP5 7 16...

Page 17: ...ESPLOSI EXPLODED DRAWINGS CLAT E EXPLOSIONZEICHNUNGEN AP5 17...

Page 18: ...ESPLOSI EXPLODED DRAWINGS CLAT E EXPLOSIONZEICHNUNGEN AP7 18...

Page 19: ...19...