Installation & Operation Manual

SAF-X

01.2022

/

001301

-

910101

9

5.

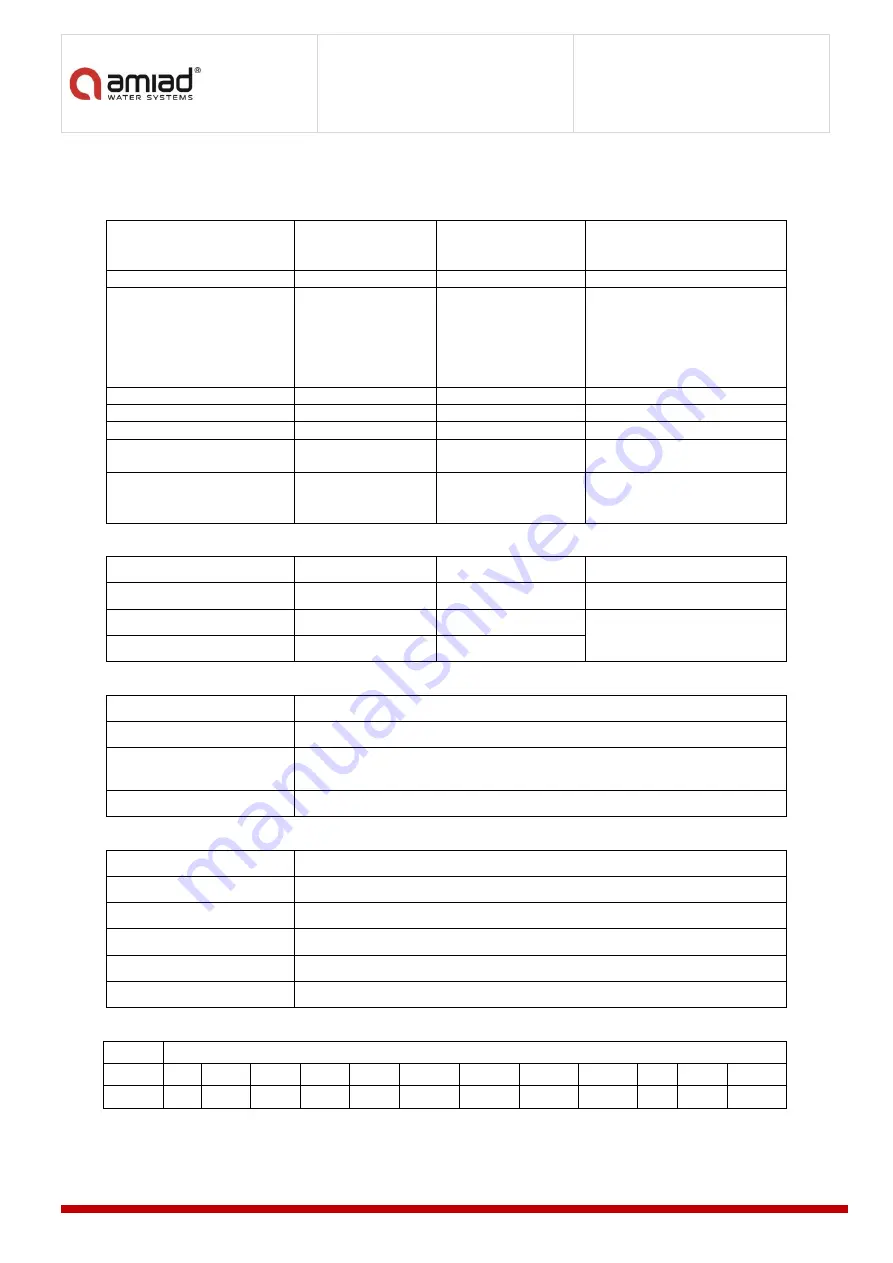

Technical Specifications SAF-X 3000

General

Maximum flow rate

160 m

3

/hr

700 gpm

Consult manufacturer for

optimum flow depending on

filtration degree & water quality.

Design Pressure

10 bar(g)

150 psi

Min. Operating pressure

2.0 bar(g)

30 psi

Pressure is critical during the

flushing cycle.

Consult manufacturer for the

required values according to

filtration degree and operation

conditions.

Temperature Min / Max

4

0

/ 50

0

C

39.2

0

/ 122

0

F

Filtration area

3000 cm

2

465 in

2

Inlet/Outlet diameter

80,100,150 mm

3", 4", 6"

Flange standards as per request.

Filter housing

250 mm

10"

Epoxy-coated steel, or other on

request.

Weight: empty / Operation

80 mm = 118/188 Kg

100 mm = 121/191 Kg

150 mm = 126/196 Kg

3" = 260/414 lb.

4" = 266/420 lb.

6" = 277/431 lb.

Flushing Data

Exhaust valve

50 mm

2"

Flushing cycle time

20 seconds

20 seconds

Reject volume per cycle

78 liter

20 gallon

STD Nozzle

at 2.5 bar/35 psi

Minimum flow for flushing

14 m3/h

62 gpm

Control and Electricity

Control voltage

120 & 24 VAC or 24VDC

Electric motor

1/4 HP (0.18 kW) 50/60 Hz,

Rated operation Voltage

3 phase 208/230/380/400/415/460/575 Volt 50/60 Hz

Single phase, 120/240 Volt 50/60 Hz

Current consumption

0.6 Amp. (see electrical diagram for specific values)

Construction Materials

Filter Housing and Lid

Epoxy-coated carbon steel 37-2 (Stainless Steel 316 available on request).

Screens

Stainless Steel 316

Cleaning mechanism

Stainless Steel 316, POM, PVC

Exhaust valve

Epoxy-coated cast iron, Natural Rubber

Seals

Synthetic Rubber

Control

Aluminum, Brass, Stainless Steel, PVC

Standard Filtration Degrees

Stainless Steel Weave-wire Screen

micron

800

500

300

200

130

100

80

50

40

30

20

10

mm

0.8

0.5

0.3

0.2

0.13

0.1

0.08

0.05

0.04

0.0

3

0.02

0.01