Sample Temperature Effects on Readings

Refractive Index is a physical property of a material. Refractive index measurements, and the

percent solids results derived from them, are very dependent upon temperature. For most

samples, raising the temperature will lower the refractive index of a sample. Conversely,

lowering the sample temperature will raise the refractive index. This change in refractive index,

due to a change in temperature, will cause an apparent change in concentration unless the

reading is temperature corrected (TC). Before a sample measurement can be temperature

corrected however, the sample needs to reach thermal equilibrium with the instrument. Without

temperature equilibration, the resulting value cannot be considered accurate for direct read

values or temperature corrected (TC) values. This is the result of the sample being in a state of

thermal transition while the refractive index value is captured by the instrument. This is common

with all refractometers.

Automatic Temperature Correction (TC)

Automatic Temperature Correction (TC) is based upon three factors, refractive index,

temperature and temperature coefficient. The relationship of these three factors are used

to mathematically correct a value as though it was read at a specific temperature. The most

common temperature corrected (TC) temperature is 20 degrees C but it can differ with

individual requirements. The temperature corrected reading modes (TC) in this instrument,

are based upon sucrose temperature correction factors developed by ICUMSA. Non-sucrose

solutions will have unique temperature correction factor.

Since most uses of a refractometer is to control concentration, it is useful to eliminate the

temperature effects when viewing instrument readings. One standard method is to have

programmed custom channels that calculate the correct reading at 20 degrees C for a sample

that is being read at other temperatures. The use of a custom channel allows comparing

readings to a formula or process specification at a predetermined temperature without doing

complicated conversions. Please note, that custom channels to do temperature correction, are

specific to the material that the channel was developed for, and most likely will provide poor

readings if used for a different material.

7

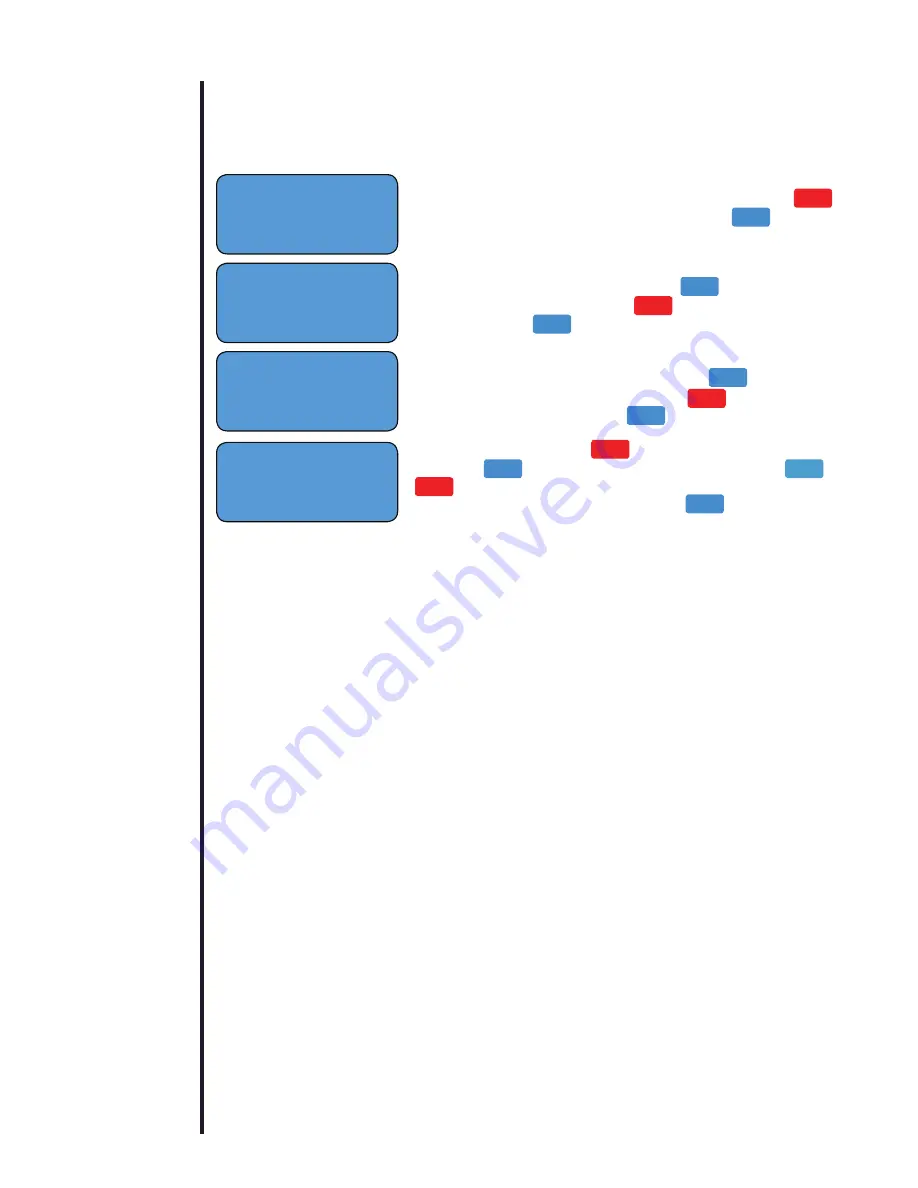

Add/Delete/Edit Calibration Points

Calibration fluid values may change from one lot to the next. It is also possible to use alternate

fluids to calibrate this instrument. As a result, it will become necessary to edit the stored values

to match any new calibration standard through the “Calibration” option menu.

To access these options from the Calibration menu press

to advance to the Add/Delete/Edit option. Press to accept

and enter the following option choices.

Add

- To add a point or turn a stored calibration point into an

active point advance to “Add” and press . Advance through

the available options by pressing . Once the optional point

is identified press to accept.

Delete

- To delete a point or turn a calibration point into an

inactive point advance to “Delete” and press . Advance

through the available options by pressing . Once the

optional point is identified press to accept.

Edit

- To edit a point press until desired point is displayed

and press to accept. Change values by pressing or

to increase or decrease the value of the indicated (^)

numeral. Once the value is correct press menu to accept.

Repeat this process until all indicated (^) values match that of the

standard that will be used for calibration.

Add/Delete/Edit

Brix-TC Brix

Edit

Brix-TC Brix

Delete

Brix-TC Brix

Add

Brix-TC Brix

↑

Read

↑

Read

↑

Read

↑

Read

↑

Read

←

Menu

←

Menu

←

Menu

←

Menu

←

Menu

←

Menu

←

Menu

↓

Calibrate

Summary of Contents for Reichert r2i300

Page 1: ...i300 REFRACTOMETER USER GUIDE...

Page 2: ......