7 1 0 0 0 7 - 1 0 0

4

13

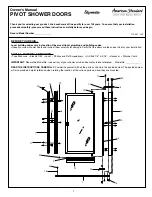

Place magnetic jamb over adjustment rail with magnetic

strip facing to outside of shower.

Close door and adjust magnetic jamb to allow 1/8" to 1/4"

clearance between magnetic jamb and door panel.

NOTE: If magnets repel each other, remove and reverse.

To adjust magnetic jamb for clearance or plumb, remove

magnetic jamb and reposition adjustment screws. Once

magnetic jamb is in desired position, secure with

mounting screws. The door may also be adjusted by

loosening the 1/4" nut, aligning strike side of door and

re-tightening door.

Install wall jamb cap by snapping in place at top of

adjustment rail. Trim with knife. For narrow strike

models, cut cap at mark with a utility knife.

Remove debris and clean threshold & base.

Caulk end of threshold at wall per detail.

Match holes in magnetic jamb with holes in adjustment rail to

determine which mounting hole is for adjustment rail only.

Remove magnetic jambs and mount adjustment rail to wall

using three #8 x 2" pan head screws. To adjust magnetic jamb

for out of plumb wall conditions, insert adjustment screws

(three #8 x 1" pan head screws) as shown.

14

ADJUSTMENT RAIL MOUNTING SCREW

#8 X 2" PAN HEAD SCREW

ADJUSTMENT SCREW

#8 X 1" FLAT HEAD SCREW

FOR “NS” MODELS,

ADJUSTMENT RAIL MOUNTING SCREW

#8 X 1-1/2" FLAT HEAD SCREW

FOR “NS” MODELS,

ADJUSTMENT SCREW

#8 X 5/8" FLAT HEAD SCREW

15

Caulk where wall jamb meets wall for entire height of unit on

both inside and outside of shower.

Caulk where threshold meets base on outside of unit only.

Allow 24 hours for silicone to cure before using shower.

Clean bottom rail.

Cut vinyl sweep the same length as drip rail. Insert sweep into

groove in drip rail.

Position drip rail on inside of doorframe 1/8" up from bottom

edge and set 1/2" from each outside edge. The drip rail must be

adjusted so that it angles down towards pivot side and does not

hit threshold or doorjambs when door is closed.

Mark the proper location and then remove backing from tape

and press drip rail in place. Apply a small dab of silicone into

the strike end of the drip rail before inserting plastic plug.

Note: Allow 24 hours for adhesive to cure before using shower.

16

SILICONE

CAULK

ADJUSTMENT

SCREW

ADJUSTMENT RAIL

ADJUSTMENT RAIL

MOUNTING SCREW

MAGNETIC

JAMB

MATCH

HOLES

3 PLACES

MAGNETIC

JAMB

MOUNTING

SCREW

WALL JAMB CAP

ADJUSTMENT

SCREW

DOOR

MAGNETIC

JAMB

MAGNETIC

JAMB

MOUNTING

SCREW

ADJUSTMENT

RAIL

1/8"-1/4"

ANGLE DOWN

ABOUT °1

VINYL

SWEEP

DRIP RAIL

DRIP CAP

INSIDE VIEW

SILICONE

SILICONE

OUTSIDE VIEW