7 1 0 0 0 7 - 1 0 0

3

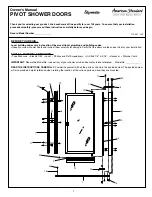

On side opposite pivot jamb, drill a 1/8" hole in threshold

located 5/8" from wall and 7/8" from flat edge of threshold.

Fasten positioning spacer to threshold using one #8 x 1"

pan head screw.

For doors with narrow strikes (e.g. Model #804NS) position-

ing spacer is not necessary. Instead mark a line 7/8" in from

flat edge and parallel to it. Center adjustment rail over this

line when installing in step #12.

Temporarily secure threshold with masking tape at strike

side. Ensure an even distance between edge of threshold

and front of the base.

Locate adjustment rail over positioning spacer and against

wall (you may reverse rail to mark holes). Use a level to

plumb adjustment rail.

Mark hole location of the large holes only. Remove rail. Drill

six 3/16" diameter holes then insert wall anchors.

12

11

#8 x 1-1/2" Phillips Flat Head Screw (Actual Size)

7

8

Remove pivot jamb with threshold. Drill six holes using a

3/16" drill bit. (Use a masonry bit for ceramic tile.)

Insert one screw anchor in each hole.

NOTE: When drilling into fiberglass or plastic walls, use a

1/8" drill bit and do not use screw anchors.

Apply 1/4" bead of silicone caulk where bottom of pivot

jamb and threshold meet (see inset detail).

Mount assembled pivot jamb to wall using six #8 x 1-1/2"

flat head screws.

9

Subtract door panel width DW from length W in step 1. If

difference is from 1-3/4" to 3-1/8" use the minimum hole.

If difference is from 3-1/8" to 4-1/2" use maximum hole.

Insert one nylon pivot bushing in each of selected holes top

and bottom.

Install door by mating bottom pivot bolt with nylon pivot bushing.

Align door with top pivot arm and insert pivot bolt through arm

into 1/4" nut, and then into corresponding nylon pivot bushing.

Adjust door by sliding it in pivot slot top and bottom to allow

1-3/8" to 1-7/8" of space between wall and magnet side of door

when in closed position.

Tighten nut against pivot arm for proper tension using 1/4"

wrench.

SCREW ANCHOR

10

SILICONE

CAULK

DOOR

WIDTH

DW

W

IF

1-3/4" < W – DW < 3-1/8"

USE

MINIMUM

ADJUSTMENT HOLE

IF

3-1/8" < W – DW < 4-1/2"

USE

MAXIMUM

ADJUSTMENT HOLE

MIN

HOLE

MAX

HOLE

NYLON PIVOT

BUSHING

1/4" WRENCH PROVIDED

5/8"

7/8"

POSITIONING

SPACER

ADJUSTMENT

RAIL

TOP VIEW

#8 x 1" Pan Head Screw (Actual Size)

Plastic Screw Anchor (Actual Size)

W inches

— DW inches

inches