24

18-CD24D1-2

Installer’s Guide

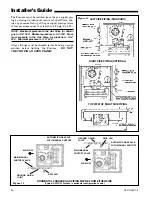

For complete shutdown: Turn the gas cock knob on the

main Gas Valve to the “OFF” position (See Figures 14 &

15).

Disconnect the electrical supply to the unit.

SEQUENCE OF OPERATION

NOTE: Whole House Air Cleaner is energized when

blower is operating and there is a call for heat or cool.

This can result in brief periods of blower operation

with the whole house air cleaner off. This can occur

during the heat fan off period or if the enhanced

mode of operation is chosen for cooling.

Comfort Control call for heat (2-Stage Comfort Control)

Call for 1st Stage only:

W1 Comfort Control contacts close signaling the control

module to run its self-check routine. After the control

module has verified that the 1st Stage Pressure Switch

contacts are open and the Limit Switch(es) contacts are

closed, the draft blower will be energized.

As the induced draft blower comes up to speed, the

Pressure Switch contacts will close and the ignitor

warm up period will begin. The ignitor will heat for

approx. 20 seconds, then the Gas Valve is energized in

1st Stage to permit gas flow to the burners.

The flame sensor confirms that ignition has been

achieved within the 4 second ignition trial period.

As the flame sensor confirms that ignition has been

achieved, the delay to fan ON period begins timing and

after approx. 45 seconds the indoor blower motor will be

energized at low speed and will continue to run during

the heating cycle. The whole house air cleaner will en-

ergize.

Call for 2nd Stage after 1st Stage:

W2 Comfort Control contacts close signaling a call for

2nd Stage Heat. After a 30 second delay, the induced

draft blower will be energized on high speed and the

2nd Stage Pressure Switch contacts will close. The Gas

Valve is energized in 2nd Stage and the indoor blower

motor in high speed.

2nd Stage satisfied, 1st Stage still called:

W2 Comfort Control contacts open signaling that 2nd

Stage Heating requirements are satisfied.

The induced draft blower is reduced to low speed allow-

ing the 2nd Stage Pressure Switch contacts to open and

the Gas Valve is reduced to 1st Stage. The indoor

blower motor is reduced to low speed.

1st stage satisfied:

W1 Comfort Control contacts open signaling that 1st

Stage heating requirements are satisfied. The Gas

Valve will close and the induced draft blower and the

whole house air cleaner will be de-energized. The in-

door blower motor will continue to run for the fan off

period (Field selectable at 60, 100, 140 or 180 seconds),

then will be de-energized by the control module.

Comfort Control call for heat (1-Stage Comfort

Control)

W1/ W2 (jumpered) Comfort Control contacts close sig-

naling a call for heat. 1st Stage sequence of operation

remains the same as above. 2nd Stage Heat will ener-

gize after the Stage delay timer (10 minutes) has ex-

pired.

Comfort Control satisfied:

W1/ W2 (jumpered) contacts close signaling the control

module to close the Gas Valve. The induced draft blower

is switched to low speed and de-energized after the post

purge timer has expired. The indoor blower motor will

continue to operate after the flames are extinguished

and then is switched to low heat speed for the FAN-

OFF period. The whole house air cleaner will be de-en-

ergized.

NOTE TO INSTALLER

Review warnings and the contents of USER’S INFOR-

MATION MANUAL with the homeowner when installa-

tion is complete and equipment is ready to be turned

over to the homeowner for normal operation.

CONTROL AND SAFETY SWITCH

ADJUSTMENT

LIMIT SWITCH CHECK OUT

The limit switch is a safety device designed to close the

Gas Valve should the Furnace become overheated.

Since proper operation of this switch is important to the

safety of the unit, it

must be checked out on initial

start up by the installer

.

To check for proper operation of the Limit Switches, set

the Comfort Control to a temperature higher than the

indicated temperature to bring on the Gas Valve. Re-

strict the airflow by blocking the return air or by dis-

connecting the blower. When the Furnace reaches the

maximum outlet temperature as shown on the rating

plate, the burners must shut off. If they do not shut off

after a reasonable time and overheating is evident, a

faulty Limit Switch is probable and the Limit Switch

must be replaced. After checking the operation of the

Limit Control, be sure to remove the paper or card-

board from the return air inlet, or reconnect the

blower. Refer to the Service Facts for additional in-

structions.

INDOOR BLOWER TIMING

▲

WARNING

!

DISCONNECT POWER TO THE UNIT BEFORE REMOV-

ING THE BLOWER DOOR.

FAILURE TO FOLLOW THIS WARNING COULD RESULT

IN PROPERTY DAMAGE, PERSONAL INJURY OR

DEATH

.