1-34

American-Lincoln

®

SC7740

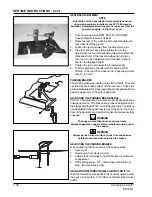

CHECKING ENGINE OIL LEVEL

1. Be sure the machine is parked on level ground.

2. To check the oil level, draw out the dipstick (1), wipe it clean,re-insert it, draw it out again. Check to see that

the oil level lies between the two notches.

3. If the level is too low, add new oil of the same make and viscosity to the specified level.

4. If the oil intended to bring up the level is of a different make and/or viscosity, a complete oil change should

be done. Never mix two different types of oil.

NOTE

Use the proper Engine Oil SAE according to the ambient temperatures.

CHANGING ENGINE OIL

1. The oil should be changed after the initial 50 hours of operation and every 200 hours thereafter. After warming

up, stop the engine.

2. Position a waste container appropriately, remove the oil plug and drain old oil completely.

3. Replace the plug securely.

4. Add new oil up to the upper limit of the oil level gauge.

WARNING

The API classification of the engine oil should be SF class grade.

Change the type of oil according to the ambient temperature of SAE viscosity grade.

Above 77° F (25° C)

32° F - 77° F (0° C - 25° C)

0° F - 32° F (-32° C - 0° C)

SAE 30 or SAE 10W30

SAE 20 or SAE 10W30SAE

10W or SAE 10W30

5. To change the engine oil filter cartridge, remove cartridge with a filter wrench; apply film of engine oil to the

rubber gasket on the new cartridge and screw in by hand.

WARNING

Overtightening may cause deformation of the rubber gasket. After the cartridge has been replaced,

engine oil normally decreases a little. Check the oil level and add new oil to the specified level.

NOTE

After the cartridge has been replaced, the engine oil level normally decreases a little. Run the

engine for a while and check for seal leaks before checking the engine oil level. Add oil if necessary.

FAN BELT TENSION

1. Measure the deflection (tension) by depressing the belt halfway between the fan drive pulley and the

alternator pulley at 98 N (10 kgf, 22 lbs.) of force. Factory specification for fan belt tension is 0.28 to 0.35

inches (7 to 9 mm).

2. If the measurement is not correct, loosen the alternator mounting bolts and, using a lever places between the

alternator and the negine block, pull the alternator out until the belt deflection falls within acceptable range.

Tighten mounting bolts (under load of 10 kgf (22.1 lbs)).

3. Always replace a damaged belt.

DRIVE BELT TENSION

1. Loosen the 4 bolts on the plate.

2. loosen the jam nut on the bolt.

3. Torque the bolt to 120 in/lbs. (If you do not have an in/LB torque wrench use a ft/LB torque wrench and

torque to 12 ft/lbs).

4. Tighten jam nut.

5. Tighten the 4 bolts to the plate finger tight.

GENERAL MACHINE MAINTENANCE - Cont.