1-30

American-Lincoln

®

SC7740

C1539/0002

SERVICE INSTRUCTIONS - Cont.

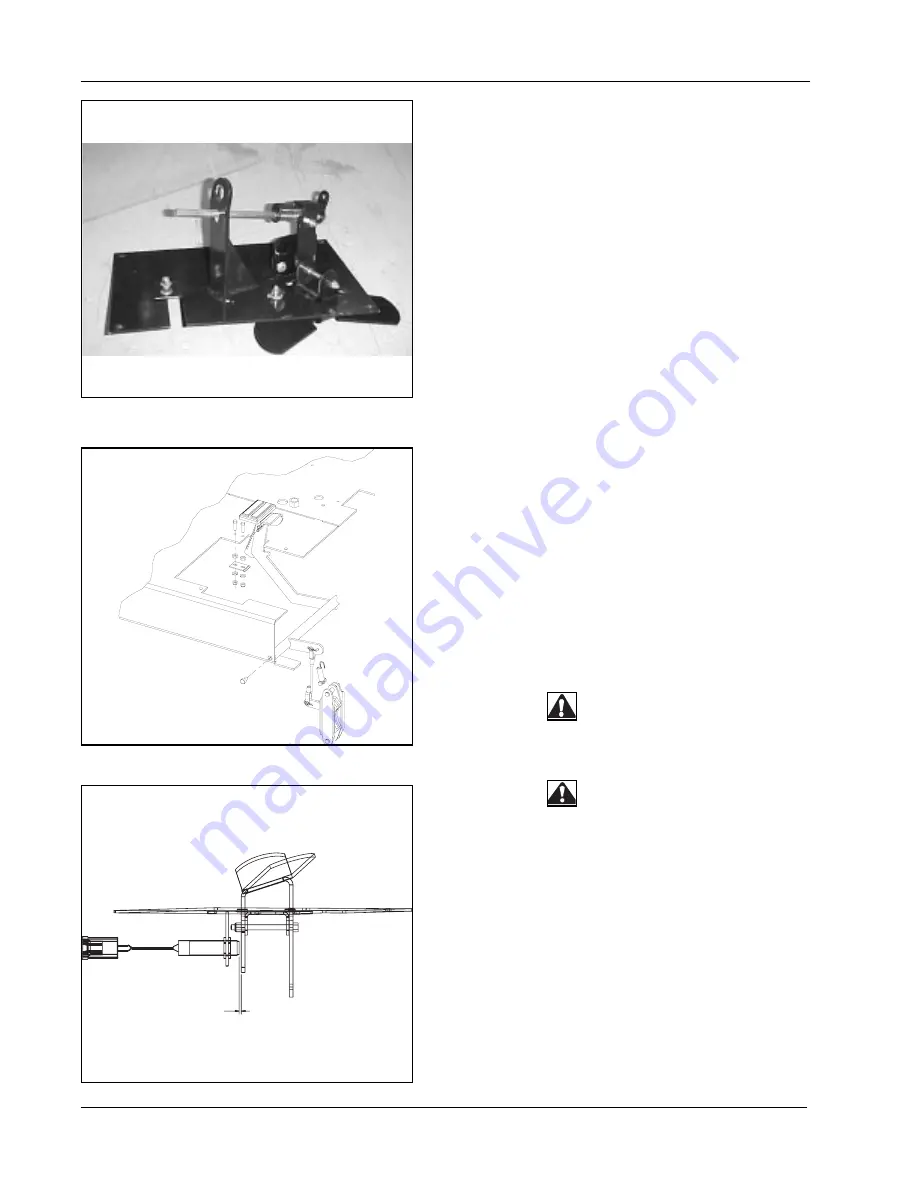

NEUTRAL ADJUSTMENT

NOTE

Orientation of the transmission arm assembly depends

upon which engine is installed in the SC7740 Sweeper

Scrubber. Adjustment directions given are as seen from the

operator’s position in the driver’s seat.

1.

Check engine no load RPM; SC7740, 2050 RPM.

Check hydraulic reservoir oil level.

2.

Raise the rear of the machine onto jack stands so the

rear wheel is off the ground.

3.

Loosen the jam nut away from the adjustment nut.

4.

If the rear drive wheel is turning forward, turn the

adjustment nut counterclockwise (this will lengthen the

threaded shaft). If the rear drive wheel is turning in

reverse, turn the adjustment nut clockwise (this will

shorten the threaded shaft).

5.

Tighten the jam nut against the threaded shaft.

6.

Test for operation of neutral with the engine at full

throttle. If the rear drive wheel turns, repeat adjustment

steps 3, 4 and 5.

PARKING BRAKES

The parking brakes are located on the front wheels. They are

operated by the brake pedal and the lock lever. Check the

parking brakes daily for proper operation and inspect the brake

pads for wear every 100 hours of operation.

ADJUSTING THE PARKING BRAKE PEDAL

Perform this adjustment to ensure proper pedal height and

linkage operation. The brakes are properly adjusted when

the brakes hold theSC7740 on an 6-degree ramp. The brakes

need adjusted if the pedal travels closer than one inch to the

floor of the operator’s compartment when the brakes are fully

engaged.

WARNING

The hopper could fall and cause serious injury.

Always engage the hopper safety arm before working under

the hopper.

WARNING

Always park on a level surface, chock tires and observe

safety procedures when adjusting the brakes.

ADJUSTING THE PARKING BRAKES

When adjusting the brake clevis, follow these steps:

1.

Open cover.

2.

Remove pin from clevis (U-joint).

3.

Adjust clevis clockwise to tighten brakes for maximum

engagement.

4.

With parking brake “off”, rotate wheel with minimum

drag. (Not completely free)

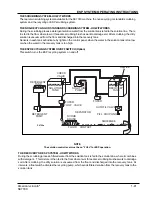

ADJUSTING THE DIRECTIONAL CONTROL SWITCH

With the foward/reverse pedal in the neutral position,adjust

the switch so it is within .100” of face on thedirectional control

pedal.

.10