4

American Dryer Corp.

113574 - 4

Installation Procedures __________________

Location Requirements

The temperature of the installation location must remain

between 4° C and 55° C.

The dryer must not be installed or stored in an area where it

will be exposed to water and/or weather.

The dryer should be located where a minimum amount of

exhaust ducting will be necessary.

The dryer must be installed on a sound level floor capable of

supporting its weight. Any carpeting must be removed.

Install a lockable door to prevent the public from accessing the

rear of the dryer.

The appliance must not be installed behind a lockable door, a

sliding door or a door with a hinge on the opposite side to that

of the tumble dryer, in such a way that a full opening of the

tumble dryer door is restricted.

Unpacking / Setting Up

Dryer must be handled in an upright position at all times.

Remove protective shipping material (i.e. plastic wrap and

optional shipping box) from the dryer.

Remove the pallet. Remove the 4 bolts securing the base of

the dryer to the pallet (one in each corner of the cabinet base).

Remove the back guard for access to the 2 rear bolts. Remove

the bottom lint door to reach the 2 front bolts.

If the dryer is to be slid into its final position, ensure that all four

leveling legs (one in each corner) are extended slightly so the

dryer will slide on these legs (not the cabinet frame).

Once the dryer is in position, adjust the leveling legs so it is

level front-to-back and side-to-side.

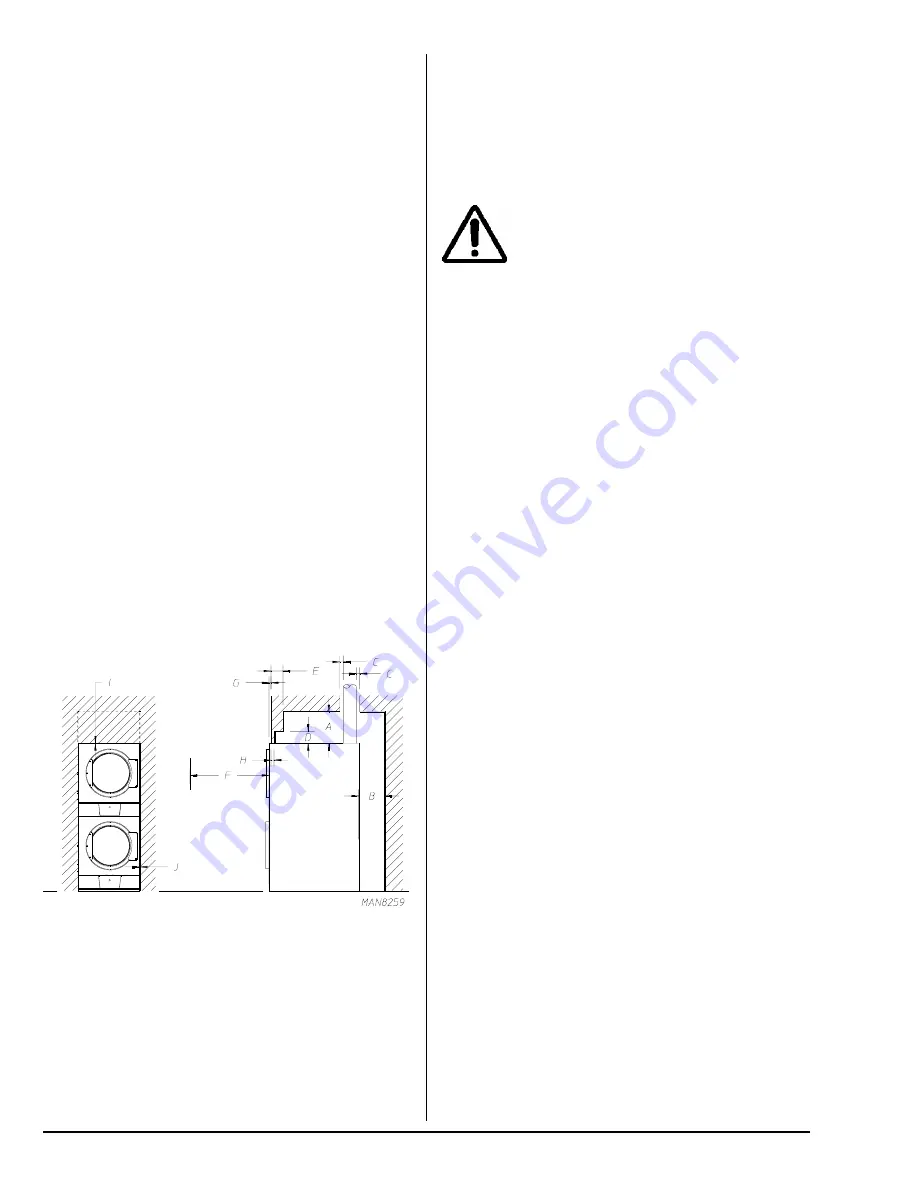

Dryer Enclosure Requirements

Clearance to combustible material

A

Minimum 30 cm (46 cm recommended)

B

Minimum 30 cm (61 cm recommended)

C

Minimum 5 cm

D

Minimum 10 cm

E

Maximum 10 cm

Clearance to nearest obstacle

F

Open door: AD-30x2: 76 cm, AD-45x2: 82.6 cm

G

2.5 cm

H

2.5 cm

I

1.5 mm

J

1.5 mm

Fresh (Make-Up) Air Supply

Requirements

The dryer draws in air, heats it, passes it through

the tumbler, and exhausts it outside.

Adequate ventilation has to be provided to avoid the back flow

of gases into the room from appliances burning fuels, including

open fires.

Insufficient fresh air supply could diminish dryer performance.

Make-up air must be free of dry cleaning solvent fumes.

Locate fresh air openings away from exhaust vent discharge.

Locate the openings behind the dryer to avoid room drafts.

An unrestricted opening to the outdoors of 928 cm

2

for each

AD-30x2 and 1,210 cm

2

for each AD-45x2 is required (Based

on 22 cm

2

per kW).

Separate make-up air openings are not required. Common

openings, located evenly between the dryers, are acceptable.

The size of the make-up air opening must be increased by

33% to compensate for the use of registers or louvers.

Exhaust Requirements

Single (independent) dryer venting is recommended.

Dryers must be exhausted to the outdoors.

The dryer shall not be exhausted into any gas vent, chimney,

wall, ceiling, or concealed space of a building.

Exhaust ductwork should be designed and installed by a

qualified professional. Improperly sized ducting will result in

slow drying and possible dryer malfunction.

Exhaust back pressure should be a minimum of 0mb and a

maximum of 1.0mb.

The design of the flue system shall be such that any condensate

formed when operating the appliance from cold shall either be

retained and subsequently re-evaporated or discharged.

Use metal ducting or other noncombustible material.

Avoid 90° turns; use gentle (30° or 45°) bends instead.

Elbow radius should be at least 1.5 times the duct diameter.

Avoid using screws or other fasteners that project into the

exhaust airflow and collect lint.

There must be 5 cm of clearance if the duct passes through

any wall, ceiling, or roof made of combustible materials.

Protect the end of the exhaust duct from the weather outside.