8

U

SE

REFRIGERANT

CERTIFIED

TO

AHRI

STANDARDS

. U

SED

REFRIGERANT

MAY

CAUSE

COMPRESSOR

DAMAGE

,

AND

THE

WARRANTY

. M

OST

PORTABLE

MACHINES

CANNOT

CLEAN

USED

REFRIGERANT

TO

MEET

AHRI

STANDARDS

.

IS

NOT

COVERED

UNDER

CAUTION

Start-up Procedure Detail

Liquid and suction valves on condensing unit are closed to

contain the charge within the unit. The unit is shipped with

the valve stems closed and caps installed. Do not open

valves until the indoor coil and line set is evacuated.

CAUTION

Prolonged operation at suction pressures less than 20 PSIG

for more than 5 seconds will result in overheating of the

compressor and permanent damage to it.

1. Connect the vacuum pump with

500

micron capability

to the service valves.

2. Evacuate the system to

500

microns or less using

gas and liquid service valves. Using both valves is

necessary.

3. Close pump valve and hold vacuum for 10 minutes.

Typically pressure will rise during this period.

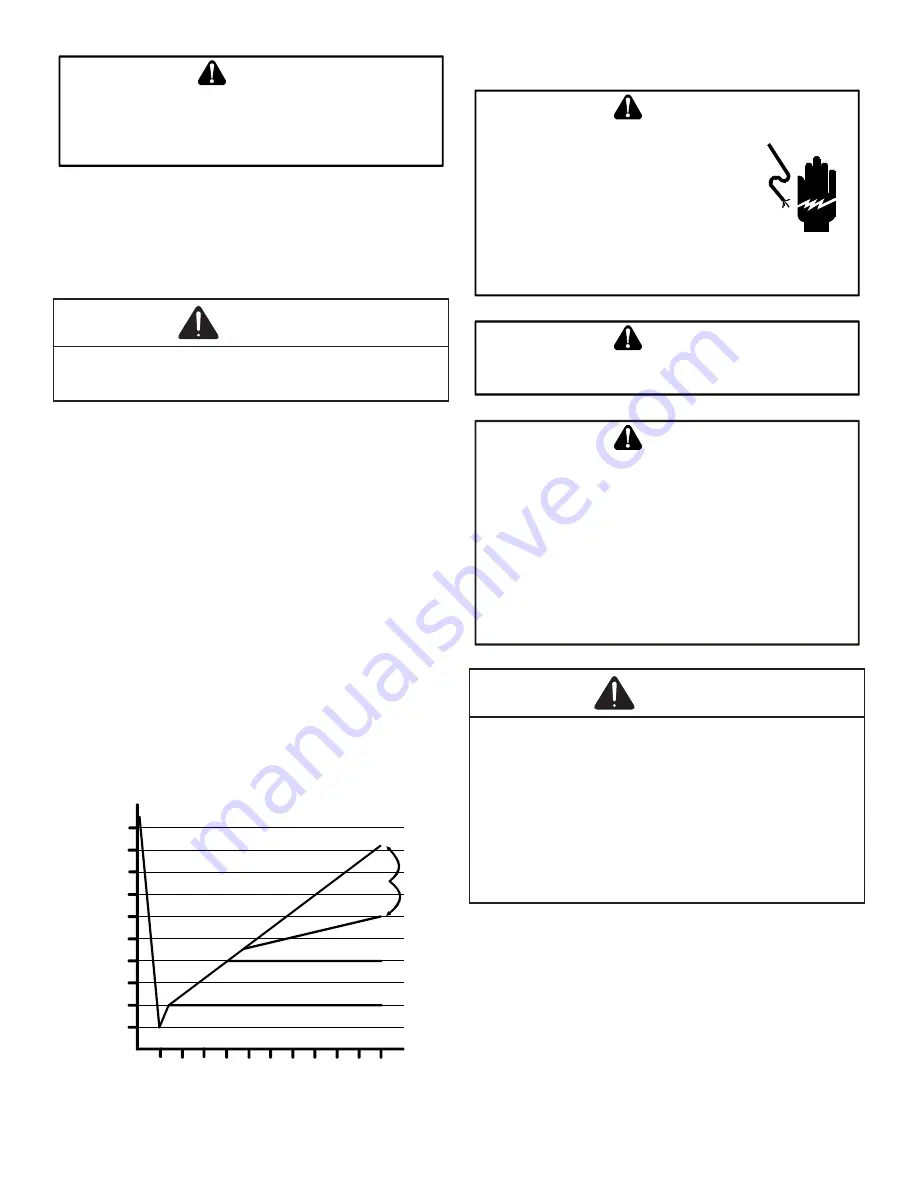

• If the pressure rises to 1000 microns or less and

remains steady the system is considered leak-

free; proceed to start-up.

• If pressure rises above 1000 microns but holds

steady below 2000 microns, moisture and/or

noncondensibles may be present or the system

may have a small leak. Return to step 2: If the

same result is encountered check for leaks as

previously indicated and repair as necessary then

repeat evacuation.

• If pressure rises above 2000 microns, a leak is

present. Check for leaks as previously indicated

and repair as necessary then repeat evacuation.

5000

4500

4000

3500

3000

2500

2000

1500

1000

500

0 1 2 3 4 5 6 7 8 9 10

LEAK(S)

PRESENT

MINUTES

V

ACU

UM

IN

MI

CR

O

NS

CONDENSIBLES OR SMALL

LEAK PRESENT

NO

LEAKS

NO

CONDENSIBLES

ELECTRICAL CONNECTIONS

HIGH VOLTAGE!

D

ISCONNECT

ALL

POWER

BEFORE

SERVICING

.

M

ULTIPLE

POWER

SOURCES

MAY

BE

PRESENT

. F

AILURE

TO

DO

SO

MAY

CAUSE

PROPERTY

DAMAGE

,

PERSONAL

INJURY

OR

DEATH

DUE

TO

ELECTRIC

SHOCK

. W

IRING

MUST

CONFORM

WITH

NEC

OR

CEC

AND

ALL

LOCAL

CODES

. U

NDERSIZED

WIRES

COULD

CAUSE

POOR

EQUIPMENT

PERFORMANCE

,

EQUIPMENT

DAMAGE

OR

FIRE

.

WARNING

T

O

AVOID

THE

RISK

OF

FIRE

OR

EQUIPMENT

DAMAGE

,

USE

COPPER

CONDUCTORS

.

WARNING

GROUNDING REQUIRED!

A

LWAYS

INSPECT

AND

USE

PROPER

SERVICE

TOOLS

. L

ACK

OF

INSPECTION

OR

IMPROPER

TOOLS

MAY

CAUSE

EQUIPMENT

DAMAGE

OR

PERSONAL

INJURY

. A

LL

DISCONNECTED

GROUNDING

DEVICES

MUST

BE

RECONNECTED

BEFORE

INSTALLING

OR

SERVICING

. M

ULTIPLE

COMPONENTS

OF

THIS

UNIT

MAY

CONDUCT

ELECTRICAL

CURRENT

;

THESE

ARE

GROUNDED

. I

F

SERVICING

THE

UNIT

,

ANY

DISCONNECTION

OF

GROUNDING

WIRES

,

SCREWS

,

STRAPS

,

CLIPS

,

NUTS

OR

WASHERS

USED

TO

COMPLETE

THE

GROUND

MUST

BE

RETURNED

TO

THEIR

ORIGINAL

POSITION

AND

PROPERLY

FASTENED

.

CAUTION

NOTICE

•

Never install a phase-advancing capacitor. As this

unit is equipped with an inverter, installing a phase-

advancing capacitor will not only deteriorate power

factor improvement effect, but also may cause capacitor

abnormal heating accident due to high-frequency waves.

•

Do not change the setting of the protection devices. If

the pressure switch, thermal switch, or other protection

device is shorted and operated forcibly, or parts other

than those specified by Goodman are used, fire or

explosion could result.

•

Do not connect the ground wire to gas pipes, sewage

pipes, lightning rods, or telephone ground wires.

The condensing unit rating plate lists pertinent electrical

data necessary for proper electrical service and

overcurrent protection. Wires should be sized to limit

voltage drop to 2% (max.) from the main breaker or fuse

panel to the condensing unit. Consult the NEC, CEC, and

all local codes to determine the correct wire gauge and

length.

Summary of Contents for VXC20 Series

Page 6: ...6...

Page 26: ...26 Troubleshooting 1 This message is displayed when using the CTK04 thermostat...

Page 27: ...27 Troubleshooting 1 This message is displayed when using the CTK04 thermostat...

Page 29: ...29 Troubleshooting 1 This message is displayed when using the CTK04 thermostat...

Page 39: ...39...

Page 40: ...40...

Page 41: ...41...

Page 57: ...57...

Page 58: ...58...