4

DFK-B

Dow nflow Kit

DFK-C

Dow nflow Kit

DFK-D

Dow nflow Kit

AVPTC 24 B14 **

AVPTC 30C 14**

AVPTC4 2D 14**

AVPTC 36C 14**

AVPTC4 8D 14**

AVPTC 48C 14**

AVPTC6 0D 14**

MODEL LIST FOR DOW NFLOW KITS

DOWNFLOW KIT

Table 2

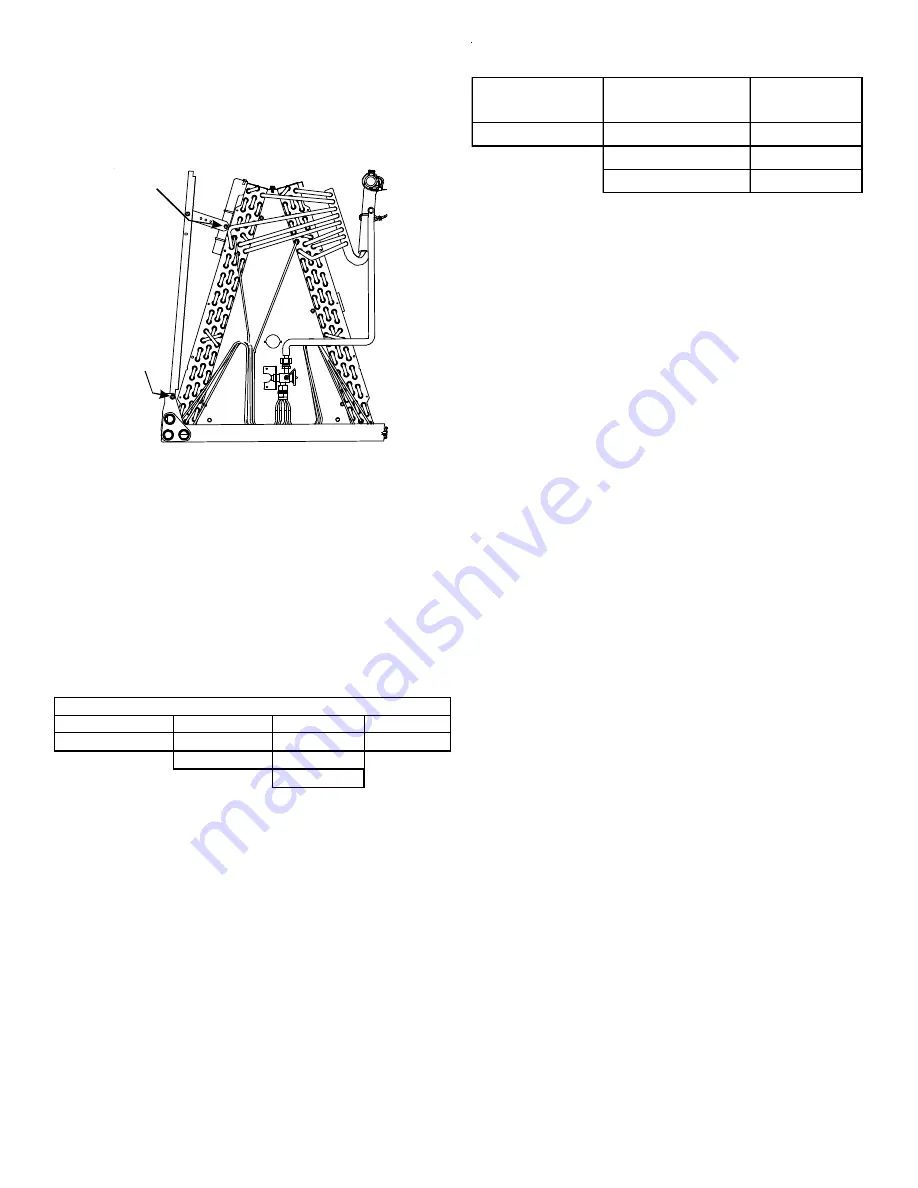

Refer to Figure 6 and 7 for the location of the compo-

nents referenced in the following steps.

1. Before inverting the air handler, remove blower access

panel and coil access panel. The coil access panel and

tubing panel may remain screwed together during this

procedure. Remove and retain the seven (7) screws se-

curing the coil access panel to the cabinet and the six

(6) screws securing the blower access panel to the cabi-

net.

2. Slide the coil assembly out using the drain pan to pull

the assembly from the cabinet.

NOTE: DO NOT USE MANIFOLDS OR FLOWRATOR

TO PULL THE COIL ASSEMBLY OUT. FAILURE TO

DO SO MAY RESULT IN BRAZE JOINT DAMAGE

AND LEAKS.

3. Removal of the center support is required on units with

21" wide cabinet. Remove and retain the two (2) screws

that secure the center support to the cabinet. Remove

the center support.

4. Using the drain pan to hold the coil assembly, slide the

coil assembly back into the cabinet on the downflow

brackets as shown in Figure 8.

5. Re-install the center support (if removed) using the two

(2) screws removed in Step 4.

6. Re-install the access panels removed in Step 1 as shown

in Figure 9.

7. The bottom left drain connection is the primary drain for

this application and condensate drain line must be at-

tached to this drain connection. The top connection of

the three drain connections on the drain pan must re-

main plugged for this application. The bottom left drain

connection is for the secondary drain line (if used).

The bottom left drain connection is the primary drain for

this application and condensate drain line must be at-

tached to this drain connection. The top connection of the

three drain connections on the drain pan must remain

plugged for this application. The bottom right drain con-

nection is for the secondary drain line (if used).

Screw

Screw

DRIP SHIELD REMOVAL

Figure 1

6.2 Horizontal Left Installation

No field modifications are permissible for this applica-

tion.

The bottom right drain connection is the primary drain for

this application and condensate drain line must be at-

tached to this drain connection. The top connection of the

three drain connections on the drain pan must remain

plugged for this application. The bottom left drain con-

nection is for the secondary drain line (if used).

CMK0001

CMK0002

CMK0003

CMK0007

AVPTC42D14**

AVPTC48D14**

AVPTC30C14** AVPTC24B14**

AVPTC60D14**

AVPTC36C14**

AVPTC48C14**

MODEL LISTS FOR HORIZONTAL LEFT KITS

Table 1

In applications where the air handler is installed in the hori-

zontal left position (

), and the return air environment sees

humidity levels above 65% relative humidity coupled with to-

tal external static levels above 0.5" e.s.p., a horizontal con-

densate management kit is available for field application. Kit

nomenclature can be found in the table above and in the

specification sheets.

6.3 Downflow/Horizontal Right Installation

IMPORTANT NOTE:

In the downflow application, to pre-

vent coil pan “sweating”, a downflow kit (DFK) is avail-

able through your local Goodman distributor. The DFK is

not supplied with the air handler and is required by

Goodman on all downflow installations. See

Table 2

for

the correct DFK and follow the instructions provided for

installation.