25

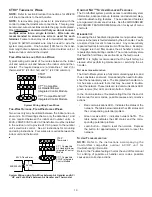

TROUBLESHOOTING

Comfor

tNet™

Ther

mostat Onl

y

S

y

m

p

toms of

A

b

normal Ope

ration

(Legac

y

& Comfor

tNet™ Thermostat)

7-Segment LED

Codes

Characters

Wi

ll

A

lter

nate

Faul

t Desc

ri

pti

on

Messa

ge Code

Possible

Causes

Correct

iv

e A

c

tions

Notes & Cauti

ons

x

Air hand

ler

blow

er fails to

opera

te

.

x

Inte

grated con

trol

module

LED

displa

y

prov

ides

indi

cated error code

.

x

ComfortNe

t™

ther

mosta

t “Call for

Serv

ice” icon il

lumi

nated

.

x

ComfortNe

t™

ther

mosta

t

scroll

s

“Check Air

Handle

r”

message

.

b0

x

Circula

tor

blow

er

motor i

s

no

t ru

nnin

g

w

hen it

should

be

running.

MO

T

O

R

NOT RUN

b0

x

Loose

w

iring co

nne

ctio

n a

t

cir

culator mo

tor

po

w

e

r leads

or circulato

r

mo

tor

pow

er

leads di

scon

nected

.

x

Failed

circulato

r blo

w

er motor.

x

Tighten or corr

ect w

iring

conne

cti

on.

x

Check

circulator

bl

ow

er

motor.

Replace i

f n

e

ce

ssa

ry

.

x

Turn pow

er OFF pri

or to

repair

x

Replace

cir

cula

tor

motor

w

ith corre

c

t

replacemen

t par

t.

x

Air hand

ler

blow

er fails to

opera

te

.

x

Inte

grated con

trol

module

LED

displa

y

prov

ides

indi

cated error code

.

x

ComfortNe

t™

ther

mosta

t “Call for

Serv

ice” icon il

lumi

nated

.

x

ComfortNe

t™

ther

mosta

t

scroll

s

“Check Air

Handle

r”

message

.

b1

x

Inte

grated

con

trol

module ha

s

lost

communication

s w

ith

cir

culator b

low

er

mot

or.

MO

T

O

R

COMM

b1

x

Loose

w

iring co

nne

ctio

n a

t

cir

culator mo

tor

co

ntrol

lead

s.

x

Failed

circulato

r blo

w

er motor.

x

Failed in

tegra

ted

control

module.

x

Tighten or corr

ect w

iring

conne

cti

on.

x

Check

circulator

bl

ow

er

motor.

Replace i

f n

e

ce

ssa

ry

.

x

Check in

tegra

ted

control

module. Repla

c

e

if

nece

ssa

ry

.

x

Turn pow

er OFF pri

or to

repair

x

Replace

cir

cula

tor

motor

w

ith corre

c

t

replacemen

t par

t.

x

Replace

inte

grated

control mod

ule w

ith

corre

ct rep

lacemen

t

part.

x

Air hand

ler

blow

er fails to

opera

te

.

x

Inte

grated con

trol

module

LED

displa

y

prov

ides

indi

cated error code

.

x

ComfortNe

t™

ther

mosta

t “Call for

Serv

ice” icon il

lumi

nated

.

x

ComfortNe

t™

ther

mosta

t

scroll

s

“Check Air

Handle

r”

message

.

b2

x

Circula

tor

blow

er

motor h

o

rse pow

er

in

shared

da

ta

se

t d

o

e

s

not ma

tch

cir

cula

tor

blow

er motor h

o

rse

pow

er.

MO

T

O

R

M

IS

M

ATCH

b2

x

Inco

rre

ct

circu

lator

blow

er

motor i

n

ai

r han

dler

blow

er.

x

Inco

rre

ct

s

hared

da

ta

se

t in

integra

ted

co

ntro

l

module.

x

Verify

cir

cula

tor

blo

w

er motor

horse

pow

er is

the

same

spe

cifie

d for

the

sp

ecific

air

handler blow

er

model.

Replace

is ne

ce

ssa

ry

.

x

Verify

shar

ed da

ta

set i

s

corre

ct for the

s

pecific

model

.

Re-populate

da

ta

u

s

ing

corre

ct

m

e

m

o

ry

car

d if

required

.

x

Turn pow

er OFF pri

or to

repair

x

Replace

motor

w

ith

corre

ct rep

lacemen

t

part.

x

Use memory

card

for

the spe

ci

fic

model

x

Inse

rt memory

card

BEFORE turning

p

o

w

e

r

ON.

Memory

c

a

rd

may

be remov

ed after

d

a

ta i

s

loaded.

x

Error

code

w

ill be

cleared

on

ce

sha

re

d

data

and mo

tor

hor

se

pow

er match

.

x

Turn pow

er off

befo

re

remov

ing memor

y

c

a

rd

x

Air hand

ler

blow

er operate

s at redu

ce

d

performan

ce

.

x

Airflow

deliv

ered is

less

than

ex

pected

.

x

Inte

grated con

trol

module

LED

displa

y

prov

ides b3

error

code.

b3

x

Circula

tor

blow

er

motor i

s

opera

ting

i

n

a

pow

er, tempera

ture

, or

speed

limiti

ng

condi

tion

.

MO

T

O

R

LIM

ITS

b3

x

Blocked

fil

ter

s.

x

Restri

ctiv

e

ductw

ork.

x

Undersi

zed

ductw

ork.

x

High

ambien

t

temp

erature

s.

x

Check filte

rs fo

r bl

o

cka

ge.

Clean fi

lter

s or

rem

ov

e

obstruction

.

x

Check du

ctw

ork fo

r blo

ckag

e.

R

e

m

o

v

e

obs

tru

ctio

n.

Veri

fy

all regi

ster

s ar

e

full

y

open.

x

Verify

duc

tw

ork i

s

appropria

tely

si

zed

for

sy

stem

. R

e

si

ze/r

e

p

lace

ductw

ork if ne

ce

ssary

.

x

See "In

s

talla

tion In

str

uction

s"

for installa

tion

requi

rements.

x

Turn pow

er OFF pri

or to

repair.

x

Air hand

ler

blow

er fails to

opera

te

.

x

Inte

grated con

trol

module

LED

displa

y

prov

ides

indi

cated error code

.

x

ComfortNe

t™

ther

mosta

t “Call for

Serv

ice” icon il

lumi

nated

.

x

ComfortNe

t™

ther

mosta

t

scroll

s

“Check Air

Handle

r”

message

.

b4

x

Circula

tor

blow

er

mo

to

r

s

e

ns

es

a l

o

ss

rotor

co

ntro

l.

x

Circula

tor

blow

er

m

o

to

r s

e

ns

es

hi

g

h

curren

t.

MO

T

O

R

TRIPS

b4

x

Abnormal mo

tor

loa

ding,

sudden

change

in speed

or

torque

,

sudd

en bl

o

cka

ge o

f air

handler blow

er/coil

air

inle

t

or

outle

t.

x

High

loading

condi

ti

ons,

blocked

fil

ter

s, v

e

ry re

stri

ctiv

e

ductw

ork, b

lockage

of air

handler blow

er/coil

air

inle

t

or

outle

t.

x

Chec

k

filt

ers,

f

ilt

er

grills/regi

sters, du

ct sy

stem

,

and air

handl

er bl

o

w

er/coil air

inlet/outl

et fo

r bl

ockages.

x

Turn pow

er OFF pri

or to

repair.