The appliance must be installed by a qualified service

technician. The oven must be properly grounded in

accordance with the National Electrical Code and

applicable local codes.

Plug the unit into a properly grounded receptacle

ONLY, positioning the unit so that the plug is easily

accessible in case of an emergency. Arcing will occur

when connecting or disconnecting the unit unless all

controls are in the “

OFF

” position.

Proper receptacle or outlet configuration or

permanent wiring for this unit must be installed by a

licensed electrician in accordance with applicable

local electrical codes.

750- and 1000-TH-II models at 208-240V are dual

rated units with a conversion switch mounted under

an access cover on the rear of the oven, near the

power cord.

With the voltage conversion switch in the 200-208V

(UPPER) position, the oven will function properly

with a source voltage of between 200 and 208.

With the voltage conversion switch in the 220-240V

(LOWER) position, the unit will function properly

with a source voltage of between 220 and 240.

NOTE:

ALL 208-240V units are shipped from the

factory with the voltage conversion switch in

the 220-240 position.

All 125V rated units will function properly with a

source voltage of between 100 and 125, 60 Hz.

The 125V rated units are provided with a cord and

plug [NEMA #5-20P]. Have a licensed electrician

install the proper outlet configuration as required for

the unit in accordance with applicable, local electrical

codes. This will assure a safe and trouble-free

installation.

230V:

To prevent an electrical shock hazard

between the appliance and other appliances or

metal parts in close vicinity, an equalization-

bonding stud is provided. An equalization

bonding lead must be connected to this stud

and the other appliances / metal parts to

provide sufficient protection against potential

difference. The terminal is marked with the

following symbol.

NOTE:

230V appliances must be connected to

an electrical circuit that is protected by

an external GFCI outlet.

E L E C T R I C A L C O N N E C T I O N

I N S T A L L A T I O N

E L E C T R I C A L - 1 0 0 0 - T H - I I

VOLTAGE

PHASE

CYCLE

/

HZ

AMPS

kW

CORD

&

PLUG

120

1

60

16.0

1.9

NEMA

5-20

P

20A - 125V

PLUG

208-240

(

AGCY

)

1

60

14.4

3.0

NO CORD

at 208

1

60

14.4

3.0

OR PLUG

at 240

1

60

11.1

2.7

230

1

50

10.4

2.4

CEE

7/7

220-230V

PLUG

D A N G E R

To avoid electrical shock, this

appliance MUST be adequately

grounded in accordance with local

electrical codes or, in the absence of

local codes, with the current edition

of the National Electrical Code

ANSI/NFPA No. 70. In Canada, all

electrical connections are to be

made in accordance with CSA C22.1,

Canadian Electrical Code Part 1 or

local codes.

Ensure that the voltage conversion switch position

and the available power source match.

PG

. 12

TH-II

INSTALLATION

/

OPERATION

/

SERVICE MANUAL

E L E C T R I C A L - 5 0 0 - T H - I I

VOLTAGE

PHASE

CYCLE

/

HZ AMPS

kW

CORD

&

PLUG

120

1

60

16

1.9

NEMA

5-20

P

20A - 125V

PLUG

208-240

(

AGCY

)

1

60

12.5

3.0

NO CORD

at 208

1

60

10.6

2.2

OR PLUG

at 240

1

60

12.2

2.9

230

1

50

12

2.8

CEE

7/7

220-230V

PLUG

E L E C T R I C A L - 7 5 0 - T H - I I

VOLTAGE

PHASE

CYCLE

/

HZ

AMPS

kW

CORD

&

PLUG

120

1

60

14.2

1.7

NEMA

5-20

P

20A - 125V

PLUG

208-240

(

AGCY

)

1

60

14.4

3.0

NO CORD

at 208

1

60

14.6

3.0

OR PLUG

at 240

1

60

11.2

2.7

230

1

50

10.4

2.4

CEE

7/7

220-230V

PLUG

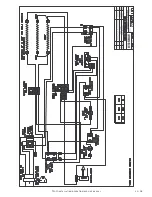

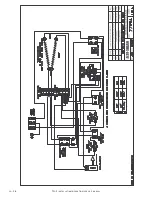

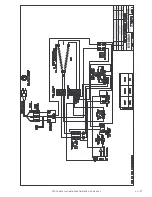

Wire diagrams are located inside the bonnet of the unit.

Summary of Contents for 1000-TH-II Split SERIES

Page 27: ...TH II INSTALLATION OPERATION SERVICE MANUAL PG 25 ...

Page 28: ...PG 26 TH II INSTALLATION OPERATION SERVICE MANUAL ...

Page 29: ...TH II INSTALLATION OPERATION SERVICE MANUAL PG 27 ...

Page 30: ...PG 28 TH II INSTALLATION OPERATION SERVICE MANUAL ...

Page 31: ...TH II INSTALLATION OPERATION SERVICE MANUAL PG 29 ...

Page 32: ...PG 30 TH II INSTALLATION OPERATION SERVICE MANUAL ...