Heatmaster 2

20

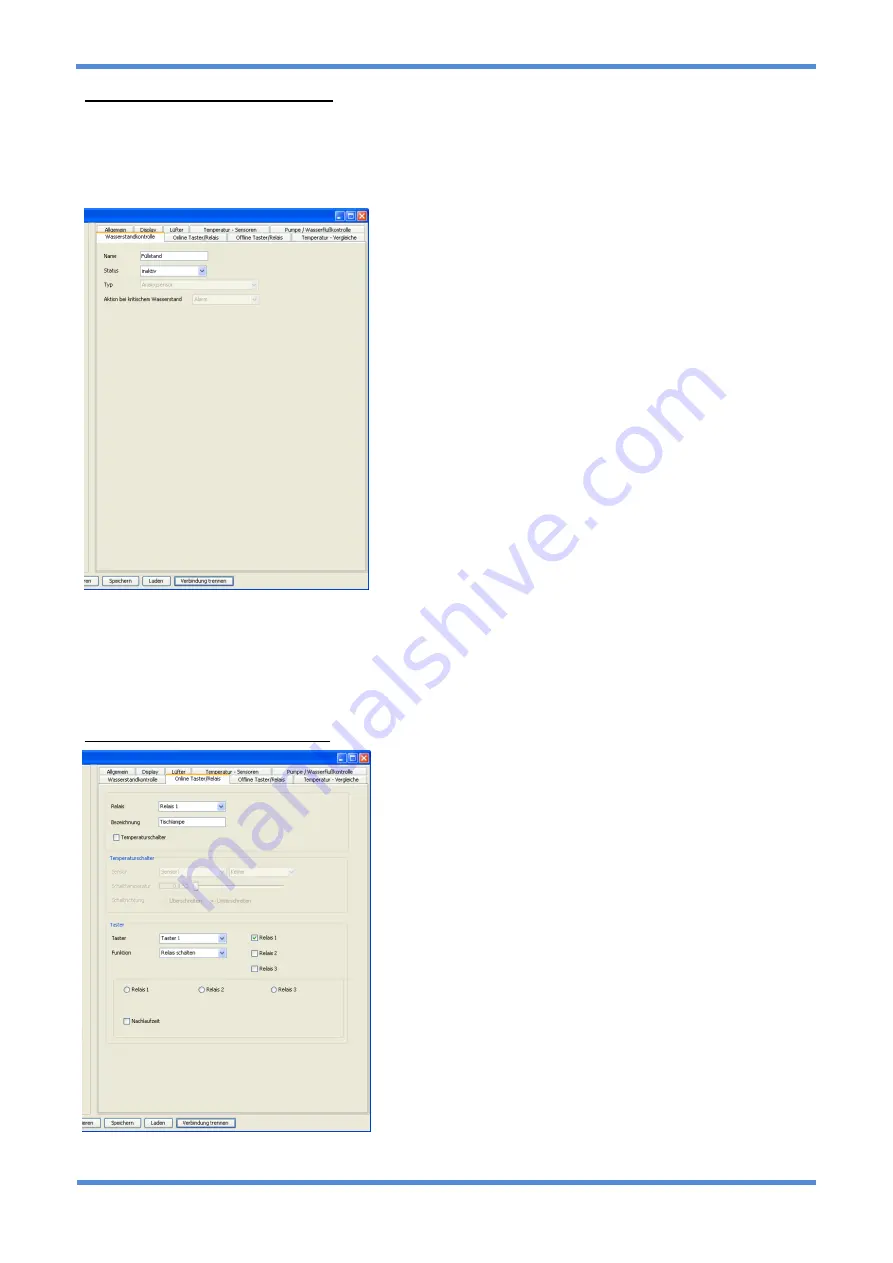

Coolant level control configuration

Name

It is possible to set a name for the coolant level sensor. The name may contain up to 255 characters made

up of letters and numbers.

Status

Sets the status of the channel to: Off, not connected or On.

Type

Here you can choose whether the connected sensor is an

analogue sensor (which actually determines the coolant level)

or a floater switch which will only give a signal when a certain

level is exceeded or undercut.

Action in case of critical coolant level

Here an action can be set for the case of a critical coolant level.

Choose from: No action, warning, alarm or emergency

shutdown.

Orientation

Set the orientation of the sensor in the reservoir here. When a

floater switch is used, it is also possible to set whether the

sensor is “closing” or “opening”

Alarm settings

With a floater switch the alarm is activated when the switch

activates. For an analogue sensor it is possible to set a “critical

level”. If this level is undercut the alarm will be activated.

Calibrate analogue sensor now

Push this button and follow the instructions. The sensor must be removed completely from the coolant and

then re-installed during the process. This allows the software to determine the conversion factor for the water

level in percent.

Online button / relay configuration

The online relay and button control allows highly complex

adjustments to be made whilst the system is running. To use

these features it is necessary to connect one or multiple relays

as well as one or multiple buttons to the Heatmaster 2. These

items will be available soon as accessories. Please check the

Alphacool product page for further information regarding

accessories. Please note that we have refrained from disabling

settings which are contradictory. Hence it is possible to make

contradicting switching procedures. The software is

programmed that in the worst case the procedures will not be

executed or will be executed with a delay in between. Please

inform yourself very thoroughly about the options and

possibilities before configuring a switching procedure.

Switching of a relay via a button

Set the relay to “manual”. At the “button” option you can now

choose

a button by choosing the option “switch relay” and

marking the according relay next to it.

Switching of a relay for a limited period of time

If a relay is intended not switch permanently when the button is

pushed, it is also possible to set a delayed switch-back of the

relay. The option “switchable via software” can be deactivated.

If the option is not active, the relay can only be controlled via a button. If the option is activated, the software