7.4. Setting the speed (Fig. 1/6/7)

First switch the machine off, then pull out the mains

plug.

The various spindle speeds can be set by moving the

V-belt.

Proceed as follows:

쎲

Remove the screw (16) in order to open the V-

belt cover (7).

쎲

Slacken the tightening screw (15) and push the

motor (8) in the direction of the machine head.

쎲

Move the V-belt to the desired position.

쎲

Refer to the table for the recommended speeds

for different drill bit materials (Fig. 7.10).

쎲

Tighten the V-belt by pushing the motor (8) back

from the machine head (6). Screw the tightening

screw (16) back down again. The tension is

properly set when the V-belt flexes in the middle

by approx. 1 cm when pressed.

쎲

Close the V-belt cover and screw down using the

screw (16).

The V-belt cover (7) must always be locked tight, as

the machine is equipped with a safety switch that

only allows the machine to be turned on when the V-

belt cover (7) is closed.

Caution!

Never let the pillar drill run when the V-belt

cover is open. Always pull the mains plug before

opening the cover. Never touch the V-belt when it is

rotating.

7.5 Drill depth stop (Fig. 8)

The drill depth can be set exactly by means of the

depth stop (14) and a scale (a) on the front side of

the machine head. The machine must be switched

off in order to set the depth stop.

쎲

Insert the required bit (7.2) and turn the setting

screws up.

쎲

Using the handle, move the bit so that its tip just

touches the surface of the workpiece and read

the value indicated on the scale.

쎲

Remove the workpiece.

쎲

Add the required drill depth to the value you read

off the scale and use the handle to lower the bit

until the value you calculated is indicated on the

scale.

쎲

Turn down the lower setting screw as far as it will

go.

쎲

Secure the setting by turning the upper setting

screw against the lower setting screw.

Important!

When setting the drill depth of a

cylindrical hole you must add the length of the drill tip

7.6. Setting the angle of the drill table (Fig. 6)

쎲

Slacken the carriage bolt (26) under the drill

table (4).

쎲

Set the drill table (4) to the desired angle (which

can be read off the scale on the top side of the

drill table).

쎲

Tighten down the carriage bolt (26) in order to

lock the drill table (4) into this position.

7.7. Setting the height of the drill table (Fig. 1/2)

쎲

Slacken the tightening screw (5).

쎲

Set the drill table (4) to the desired height by

pressing down or lifting up and simultaneously

(gently) pushing to the left or right.

쎲

Screw the tightening screw (5) back down again.

7.8. Locking the workpiece into position

As a general rule, use a machine vice (14) or another

suitable clamping device to lock a workpiece into

position.

Never hold the workpiece in place with your

hand!

When drilling, the workpiece should be able to travel

on the drill table (4) for self-centering purposes.

Ensure that the workpiece cannot rotate. This is best

achieved by placing the workpiece/machine vice on a

sturdy block.

Caution! Sheet metal parts must be clamped in to

prevent them from being torn up. Properly set the

height and angle of the drill table for each workpiece.

There must be enough distance between the upper

edge of the workpiece and the tip of the drill bit.

7.9. Drilling wood

Please note that sawdust must be properly

evacuated when working with wood, as it can pose a

health hazard. Ensure that you wear a suitable dust

mask when performing work that generates dust.

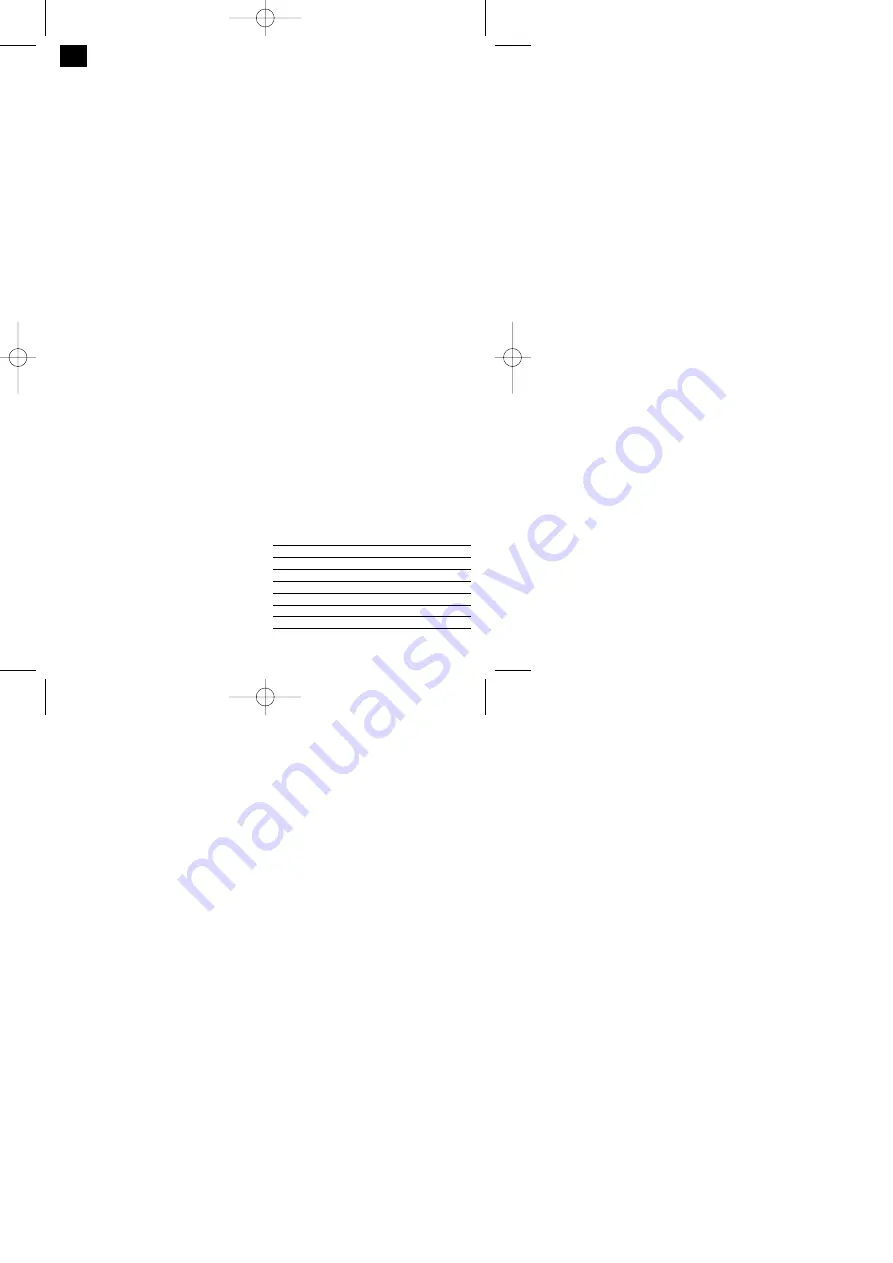

7.10. Working speeds

Ensure that you drill at the proper speed. Drill speed

is dependent on the diameter of the drill bit and the

material in question.

The table below acts as a guide for selecting the

proper speed for various materials.

Note: The drill speeds specified are merely

suggested values.

Drill bit Ø Cast iron

Steel

Iron

Aluminium

Bronze

3

2550

1600

2230

9500

8000

4

1900

1200

1680

7200

6000

5

1530

955

1340

5700

4800

6

1270

800

1100

4800

4000

7

1090

680

960

4100

3400

8

960

600

840

3600

3000

9

850

530

740

3200

2650

14

GB

Anleitung_SPK7:Anleitung SB 401-1-501-1 SKP 1 03.11.2006 13:06 Uhr Seite 14