KEENAN

MechFiber350 and 370 Operator’s Manual

33

Revision D01 21

st

May 2019

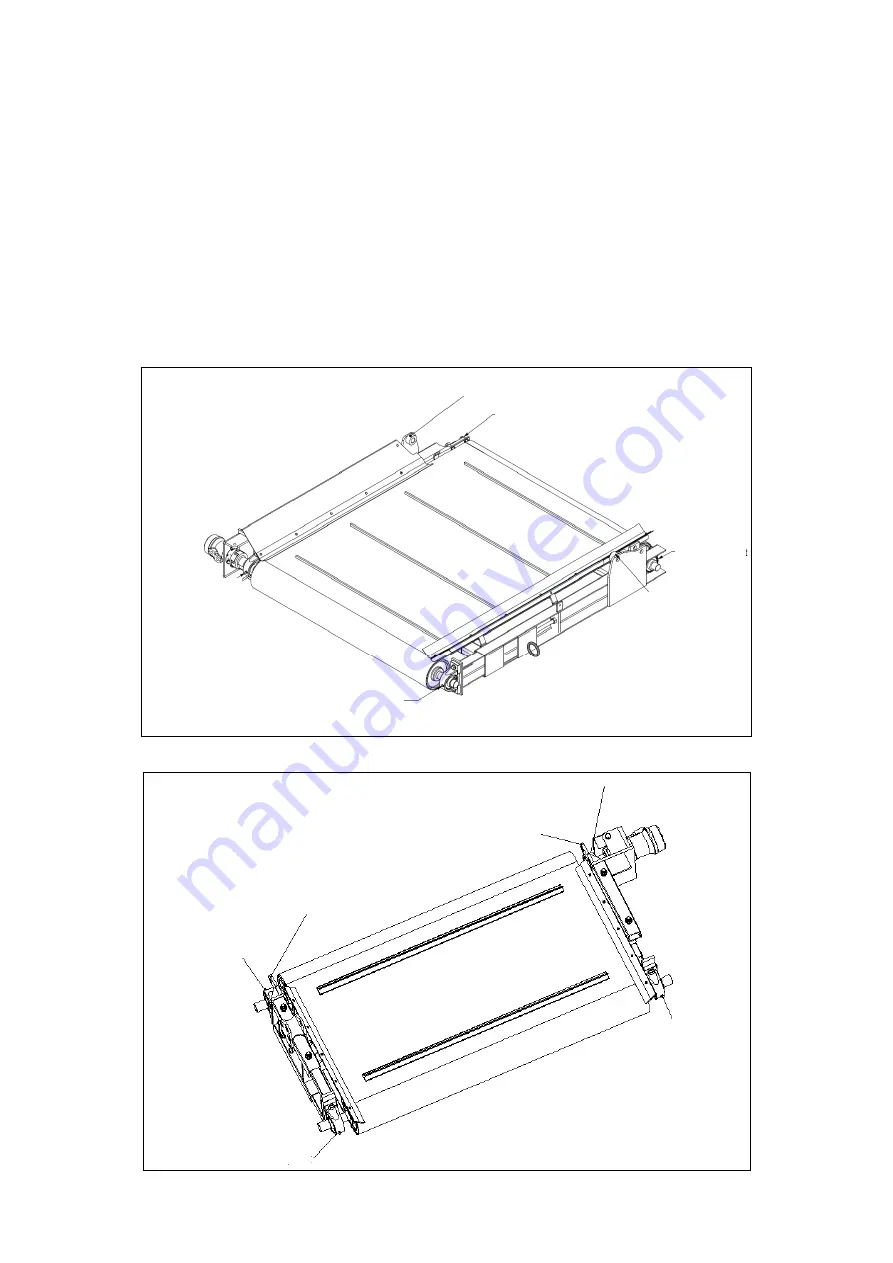

8.11 Side and stub feed-out elevator (where fitted)

An elevator system requires regular maintenance in order to achieve optimal performance.

Every week, the elevator needs to be checked to make sure that the belt is running straight

and not wearing unevenly on one side. If the belt is not running straight, adjust the tension by

adjusting the tensioner nut on the side, and run it again to check.

The elevator surface should be kept clean at all times to keep feed from building up and falling

into the rollers during operation. Do not allow old feed to build up on the sides of the belt.

Each week, ensure that the bearings are greased (as per Figures 19 and 19a below). Ensure

that the elevator is free-moving in each direction and that no feed is caught in the slideways.

Replace belts and side rubbers when they become worn; otherwise, the elevator will not

function properly.

Figure 19: Side elevator greasing points

Figure 19a: Stub elevator greasing points

Grease point

Grease point

Grease

point

Grease point

Grease point

Grease point

Grease point

Grease point

Grease point

Grease point

Grease point

Grease

point