Page 23

ALLPRO Imaging

TROUBLESHOOTING

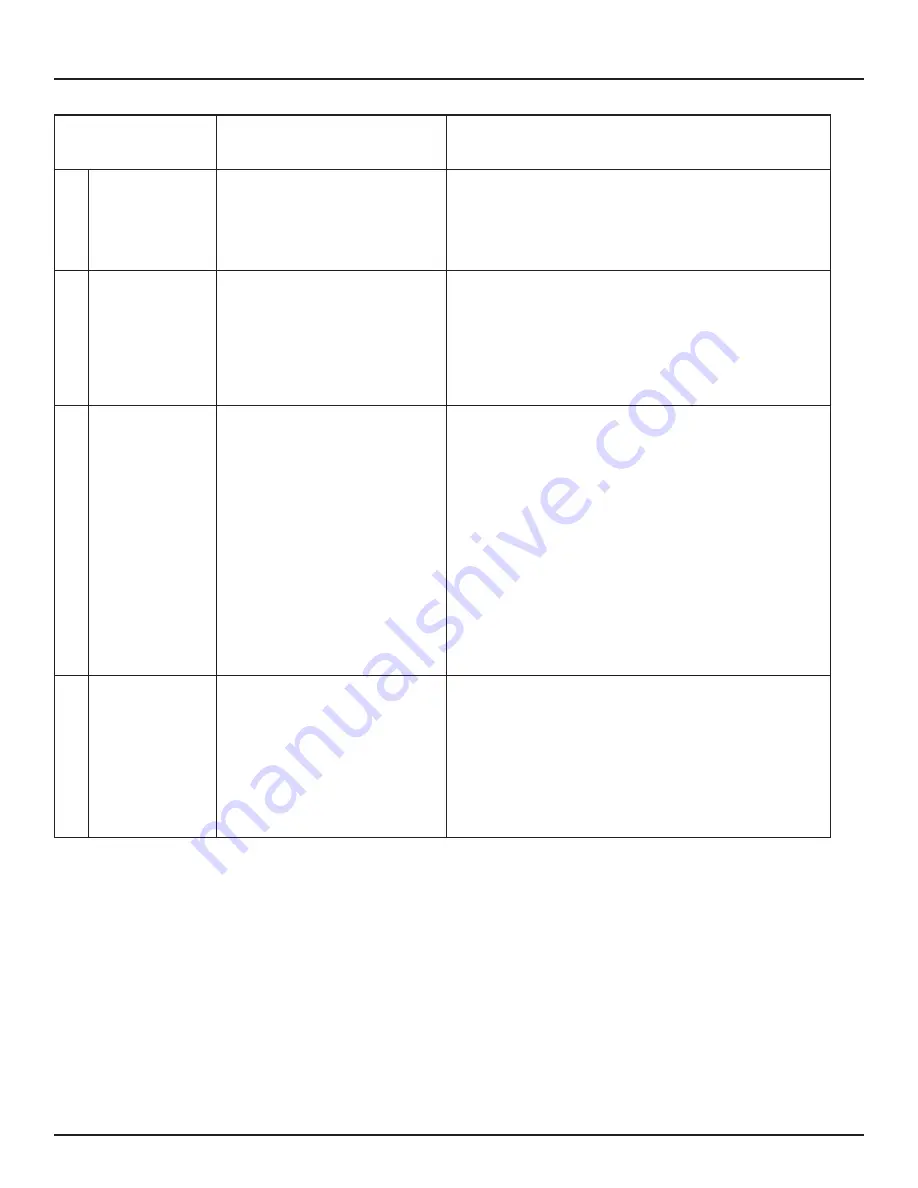

Trouble

Possible Cause

Corrective Action

6 Image is too

dark.

• PSP has been over exposed

• Use software to adjust brightness. If this is not possible,

retake image with proper (lower) exposure and a newly

erased PSP.

• Make sure intensifying screens are removed.

7 Image appears

skewed on mon-

itor.

• PSP was fed skewed.

• Worn transport belt or belt

driver.

• When inserting PSP into feed slot, be sure to “feel”

for resistance of light seal brush, align PSP, and then

push down uniformly on top edge of PSP.

• Check the plate protector tabs.

• Replace defective transport belt or belt driver.

8 Image contains

ghost images or

shadows.

• PSP was not completely

erased prior to use.

• Imaging Plate was exposed

with the back facing the

tubehead.

• PSP stored too long in cassette.

• Partial image erasure due to

exposure to light during han-

dling of the PSP

• Make sure the ScanX is operating with both eraser

strips turned on (blue LED indicator below the ERASER

switch is flashing).

• Make sure the plates are inserted properly into the

barrier envelope or cassette with the proper orientation

to the X-ray source.

• Do not store PSPs in cassettes for more than

24 hours.

• Do not leave exposed PSPs in well lit areas. Transfer

PSPs from their protective cassettes to the ScanX

within one hour of exposure.

• Make sure red erasing light emanates from both

sides of the ring.

9 Image shows

artifacts or white

or black lines.

• The PSP surface is not clean

and has dirt, stains or scratches.

• ScanX plate transport path

may contain an obstruction,

debris or dust.

• Clean the PSP with PSP wipes (P/N B8910).

• Make sure to handle plates properly.

• Do not reuse the PSP if scratched or stained.

• Clean transport path using a ScanX Cleaning Sheet

(P/N B2010 or B2020).

Summary of Contents for ScanX trek D5000-T

Page 2: ......

Page 26: ...ALLPRO Imaging Page 26 NOTES...

Page 27: ...Page 27 ALLPRO Imaging NOTES...