801805

99

Section 5 Service Procedures

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect all electric power to the machine and accessories before servicing.

• Close gas shut-off valve to gas dryer before servicing.

• Never start machine with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the machine is properly grounded.

• Washer motor not grounded! Disconnect electric power before servicing motor.

W502

WARNING

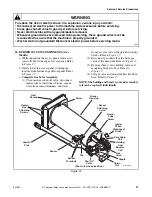

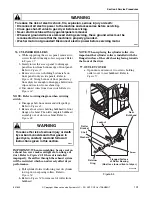

75. DRYER REAR SEAL

a. While supporting the access panel, remove two

screws from bottom edge of access panel. Refer

to Figure 27.

b. Gently lower the access panel to disengage

locators from bottom edge of front panel. Refer

to Figure 35.

c. Remove two screws holding bottom tabs on

front panel to dryer side panels. Refer to

Figure 28. Swing bottom of front panel away

from dryer far enough to disengage hold-down

clips and locators from cabinet top.

d. Disconnect wires from door switch. Refer to

NOTE: Refer to wiring diagram when rewiring

switch.

e. Remove two cabinet top hold-down screws.

Refer to Figure 48.

f. Lift cabinet top to a vertical position by hinging

it on the rear hold-down brackets.

NOTE: Cabinet top may be raised and hinged on

the rear hold-down brackets, or supported against

wall behind the dryer.

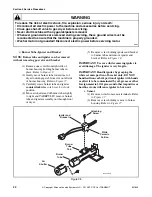

g. Disengage belt from motor and idler pulleys.

Refer to Figure 43.

NOTE: When reinstalling belt, be sure belt is

properly installed on motor and idler pulleys and is

on the correct side of the idler pulleys. Refer to

Figure 43. Belt must be positioned around center

section of cylinder approximately three inches

ahead of rear rib on cylinder with the ribbed

surface of the belt against cylinder. Refer to

Figure 52. After installing belt, manually rotate

cylinder counterclockwise to check that belt is

properly aligned.

h. Remove four screws holding bulkhead to front

flange of cabinet. Then, lift complete bulkhead

assembly out of slots in cabinet. Refer to

Figure 48.

IMPORTANT: When reassembling, be sure seal on

exhaust fan cover makes airtight seal on flange of

duct. Refer to Figure 40. If the seal is installed

improperly, the airflow through the exhaust system

will be restricted which can adversely affect dryer

performance.

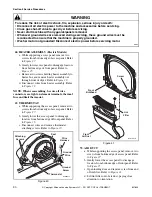

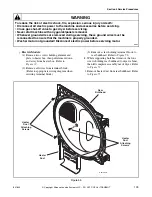

i. Manually rotate cylinder until one of the baffles

is at the 6 o’clock position and carefully remove

cylinder out through front of dryer.

j. Pull rear cylinder seal from flanged edge of

bulkhead. Refer to Figure 53.

NOTE: When installing the cylinder seal, it is

important to remember these two important steps:

(1)

The stitching on the seal must face towards the

dryer center. Refer to Figure 50.

(2)

The short flap, shown in Figure 50, must be

glued to the bulkhead and the long flap left

loose.

IMPORTANT: The seal can be adhered to the

bulkhead using replacement sealant No. 22506P.

This is accomplished by applying a bead of sealant

around the entire flanged area where the felt seal

contacts the bulkhead.

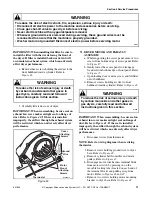

To reduce the risk of serious injury or death

by carbon monoxide and other gases in

gas dryers, carefully read and follow all

instructions given in this section.

W005

WARNING