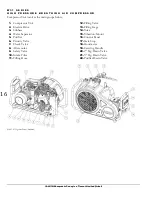

W 3 1 S E R I E S

H I G H P R E S S U R E B R E A T H I N G A I R C O M P R E S S O R

©ALKIN Kompresör Sanayi ve Ticaret Limited Şirketi

25

Electrical Panel:

It is located at the front view / left section of the compressor. It accommodates all the electrical gear to start the

motors and control the system.

Pressure Switch: (

For Auto Drain Models

)

It is located at the front view / right section of the compressor. This switch both indicates the purifier

pressure, and the set pressures on its dial, while serving as a double circuit pressure switch. It controls the

start-stop operation of the compressor. The pressure-sensing end of the pressure switch is connected to a

port on the purifier; when the pressure inside the purifier reaches the set pressure, it cuts off the control

circuit, and stops the electric motor. (See the following section for further details.)

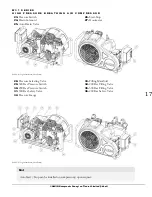

Auto Drain Valves: (

For Auto Drain Models)

The automatic drain incorporates a small piston with high pressure in the bottom, and low pressure on top;

the surface where low pressure acts on is larger than the surface where the high pressure effectively acts on

the piston. Therefore the force on the top is larger and causes the piston to sit and seal the high-pressure vent

port. The drain valves are controlled by a solenoid mounted on the pilot valve fitting. It receives compressed

air from the 2nd stage air inlet and sends it over the 2 drain valves forcing them to close. When the solenoid

is de-energized, it removes the control air over the top of the drain valve pistons, allowing the high pressure

acting from the bottom of the pistons, to open and perform drain operation.

Electric Motor:

The compressor is driven by an electric motor and is belt driven. There is a hourmeter on the control panel.

Intercoolers and Aftercooler:

These are the cooling tubes that cool down the air getting warmed after compression in stages, which are

located in interstages and at the discharge of the final stage of the compressor

INTERCOOLERS AND AFTERCOOLER ARE NOT NECESSARILY REPLACED UNLESS A

WEARING, CRACKING OR BREAKING OCCURS.

Water Separators:

They remove the water condensate from the compressed air occurred in stages under pressure. There are two

water separators on W31 Series; 2

nd

and 3

rd

Stgs.

Purifier:

This is the filtration system that purifies the compressed air to produce breathing air comply with breathing air

quality standards. Air compressed in the compressor stages finally enters the purifier. A refillable cartridge which

contains the consumables performing the filtration is placed in the purifier housing. Refillable cartridges are more