W 3 1 S E R I E S

H I G H P R E S S U R E B R E A T H I N G A I R C O M P R E S S O R

©ALKIN Kompresör Sanayi ve Ticaret Limited Şirketi

15

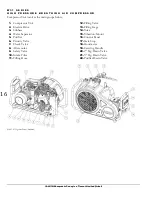

Şekil 2-Compressor Unit

W31 Series compressors are design and manufactured with intercooler serpentine located between 1

st

-2

nd

Stage cylinders, and aftercooler located at the 3

rd

Stage outlet. There are water separators at the outlet of 2

nd

Stage intercooler and at outlet of 3

rd

Stage aftercooler. Water Separators are connected to auto drain valves

that periodically drains the condensate water. The duration and frequency of opening of these drain valves are

determined by the time relay located in the electric panel. (Please see Check section.) This time relay can be

set for both functions.

There is a Safety Valve at each stage to prevent an unwanted increase in pressure resulted from a problem in

valves or any other parts. It must be periodically checked that, these safety valves are working properly and

they keep their set pressure values. (Please see Maintenance Table.)

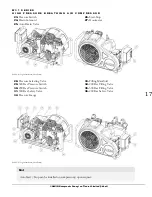

W31 Series compressors are equipped with stainless valves at each stage that are designed to maintain the

airflow without any loss of pressure. They are easy to maintain and replace. The maintenance of valves are

especially important as they are the main parts in proper and problem-free working of compressors.

Lubricants not approved by ALKIN can prevent valves from working properly due to the accumulation of

carbon on springs and washers. Valves not working properly will cause an increase in working temperature

and the deterioration of lubricant, thus in return, will further break down the valves.

Max working pressure is 350 bar and, it is dangerous and strictly prohibited to set a value higher than 350 bar.

ALKIN will not be held liable for any problems resulting from acting otherwise.

Working temperature range of the compressor is

–10/+50 ºC

.