15

WHEN TO LOOK FOR SPIDERS:

You should inspect the burners at least twice a year or immediately if any of the following conditions oc-

cur:

1. The smell of gas in conjunction with the burner flames appearing yellow.

2. The Side Burner does not reach temperature.

3. The Side Burner heats unevenly.

4. The burners make popping noises.

SIDE BURNER WON’T LIGHT:

First determine if the spark igniters are functioning properly. A rapid snapping sound should be heard

when the igniter button is depressed. If no sound is heard, check the battery. If the spark igniters are

working correctly, next determine if gas is reaching the burners. Ensure the gas supply is turned on, and

that there are no leaks according to the procedure on page 10. Attempt to match-light a burner accord-

ing to the procedure on page 12.

If the burner will light with a match, then the spark igniter may not be functioning correctly. If the burner

will not match light, and the gas supply has been confirmed, then check the burner for blockages.

FLAME IS YELLOW / GAS SMELL:

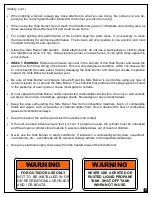

IF YOU SMELL GAS WHILE THE SIDE BURNER IS OPERATING, IMMEDIATELY TURN OFF ALL

BURNERS. Perform a leak test and check for blockages.

NOTE: If the Side Burner is operating in a dusty area or if heavy grease is present on the burner cap,

some orange tips on the burner flame should be considered normal.

BURNER BLOWS OUT:

First determine if the problem is being caused by location. Check the gas supply and flame characteris-

tics. Check to ensure that burners are correctly positioned in their bodies according to the procedure on

page 6 (assembly). Correctly installed burners should be seated firmly with no side-to-side movement.

ADDITIONAL IMPORTANT CLEANING AND STORAGE CONSIDERATIONS:

In order to maintain your Side Burner in clean working order, it will be necessary, under certain

conditions, to take additional precautions. If your Side Burner is located in a coastal area, it will

be exposed to salty air which is corrosive. If it is located close to a swimming pool or Jacuzzi

with chlorinated water, then it will be exposed to dilute hydrochloric acid which can be formed as

a result of chlorine compounds used in the pool causing chlorine to be combined with hydrogen

and water in the atmosphere. Also, muriatic acid ( another name for hydrochloric acid) is used to

maintain the correct ph balance in the pool water. Chlorine is an oxidizing agent, and as such

can promote rapid corrosion or other oxidizing processes which can damage various materials.

Type 304 stainless steel is highly resistant to corrosion but given enough exposure to such cor-

rosive conditions might succumb to some degree, such that pitting or rusting may occur. Our

Side Burner materials have been tested in saline solutions with higher salinity than sea water,

and they have been tested in highly chlorinated solutions. They have also been tested by expo-

sure to highly acidic foods. During and after these tests, we found these materials were able to

withstand exposure over prolonged periods of time. However, the above mentioned corrosive

substances, along with neglect, can lead to a situation whereby conditions might combine to

cause some damage to occur. Therefore, we suggest that you always keep your Side Burner

clean, dry and covered when not in use. This is even more important when long term storage is

intended; always store the Side Burnerl clean, dry and covered with your cover. Also, do not al-

low any food particles or grease to be left inside your Side Burner, as this will attract rodents

which, in addition to being undesirable from an hygienic standpoint, are likely to cause physical

Summary of Contents for ALSB-2

Page 1: ......

Page 2: ...2 PASTE SERIAL NUMBER LABEL IN THIS LOCATION NOTES BARBEQUE SERIAL NUMBER LABEL ...

Page 17: ...17 ...

Page 20: ...20 ...