4.6.2

Pellet feeding calibration management .................................................................................... 16

4.6.3

Managing the correction of the flue gas motor ......................................................................... 16

4.6.4

Safety thermostat .................................................................................................................... 16

4.6.5

Periodical cleaning of the furnace ............................................................................................ 16

4.6.6

Shutting down during the ignition phase .................................................................................. 17

4.7 Potential problems and solutions ........................................................................................................... 17

5.

STOVE MAINTENANCE ........................................................................................................................... 18

5.1 Routine maintenance ............................................................................................................................. 18

5.1.1

CLEANING OF THE DISPLAY AND PARTS OF THE EXTERNAL INSULATION .............................. 18

5.1.2

CLEANING OF THE CERAMIC GLASS ........................................................................................ 18

5.1.3

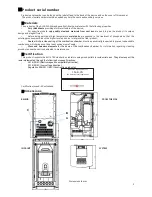

ROUTINE MAINTENANCE, ACTIVITY TYPE 1 ............................................................................. 19

5.2 Special maintenance .............................................................................................................................. 20

5.2.1

SPECIAL MAINTENANCE ACTIVITIES TYPE 2 ........................................................................... 20

5.2.2

SPECIAL MAINTENANCE ACTIVITIES TYPE 3 ........................................................................... 21

5.2.3

CHECKING OF SEALS ............................................................................................................... 21

5.2.4

CLEANING OF THE EXHAUST DUCT ......................................................................................... 21

5.3 Withdrawal from use .............................................................................................................................. 21