4 Operation

Pay attention to possible faults. Study the instructions carefully.

The items refer to the Parts list and service kits section.

4.2

Troubleshooting

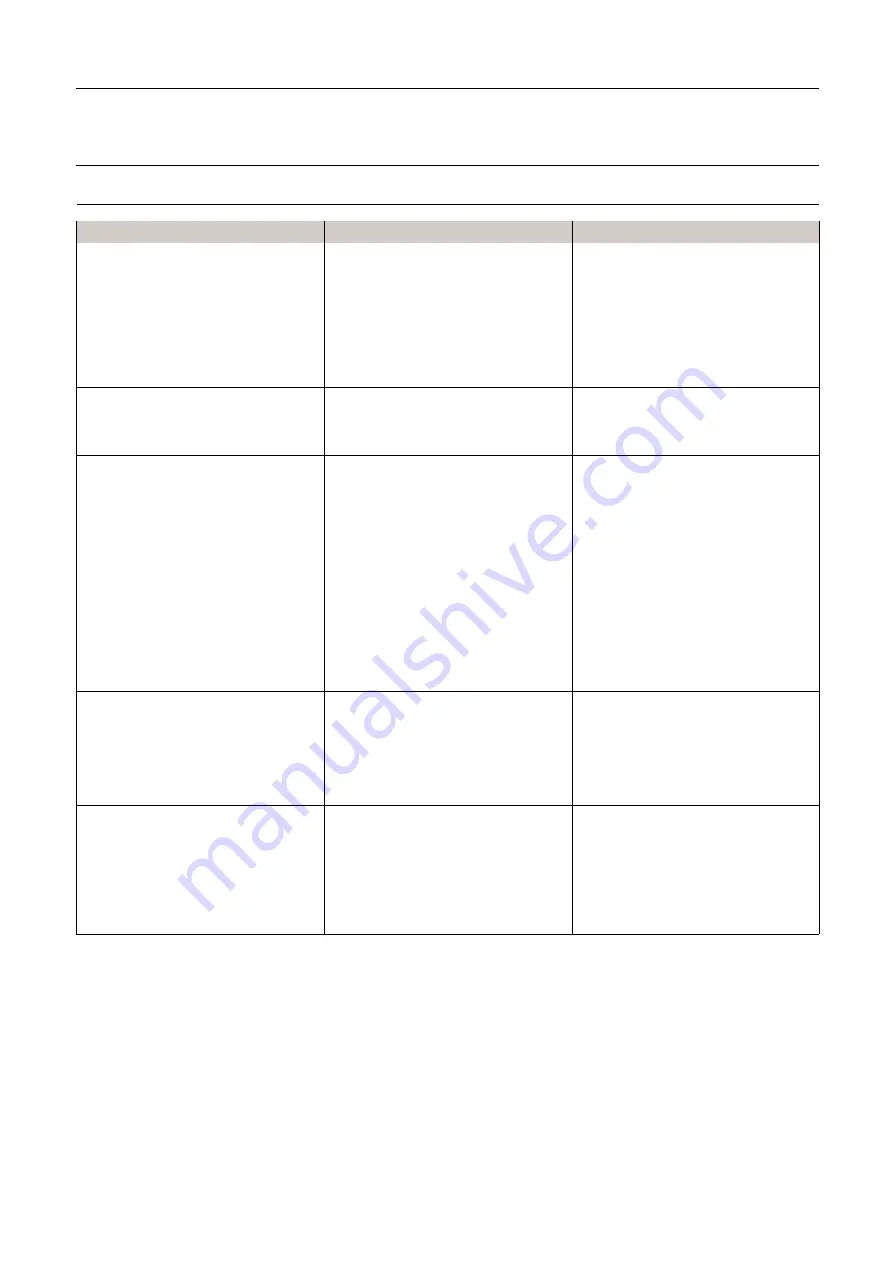

Problem

Possible cause

Repair

Manual valve does not open when

actuator is turned counter-clockwise.

1. Diaphragm has stuck.

2. Diaphragm is not properly mounted

on the actuator.

3. Actuator is broken.

4. Incorrect flow direction in combination

with high fluid pressure.

1. Inspect diaphragm and replace it if

required.

2. Correct mounting. Some force must

be used to push the actuator into the

diaphragm.

3. Inspect and replace if required.

4. Correct flow direction or lower fluid

pressure.

Manual valve does not close when

actuator is turned clockwise.

1. Incorrect flow direction in combination

with high fluid pressure.

2. Actuator is broken.

1. Correct flow direction or lower fluid

pressure.

2. Inspect and replace id required.

Pneumatic valve does not open when

opened via a solenoid valve.

1. Diaphragm has stuck.

2. Diaphragm is not properly mounted

on the actuator.

3. Actuator is broken.

4. Compressed air supply is too low.

5. Pneumatic hose is damaged.

6. Solenoid valve fault or forced in wrong

position manually.

7. Incorrect flow direction in combination

with high fluid pressure.

1. Inspect diaphragm and replace it if

required.

2. Correct mounting. Some force must

be used to push the actuator into the

diaphragm.

3. Inspect and replace is required.

4. Check compressed air supply

pressure.

5. Replace pneumatic hose.

6. Check that the solenoid valve is not

operated manually. Replace solenoid

valve.

7. Correct flow direction or lower fluid

pressure.

Pneumatic valve is open all through

closed via the solenoid valve.

1. Solenoid valve fault.

2. Electrical cable is damaged.

3. Pneumatic system does not ventilate.

4. Incorrect flow direction in combination

with high fluid pressure.

1. Inspect and replace if required.

2. Replace electrical cable.

3. Check ventilation of pneumatic

system.

4. Correct flow direction or lower fluid

pressure.

Cleaning in CIP is not satisfactory.

1. Cleaning chemicals wrong type or too

low concentration.

2. Flow too low.

3. Poor draining.

4. Flow obstructed.

5. Diaphragm broken.

1. Analyse for correct chemicals and

concentration.

2. Increase flow.

3. Check drainabillity and turn valve if

required.

4. Check flow path.

5. Replace diaphragm.

13

Summary of Contents for UltraPure Series

Page 2: ......