13

3. Operation

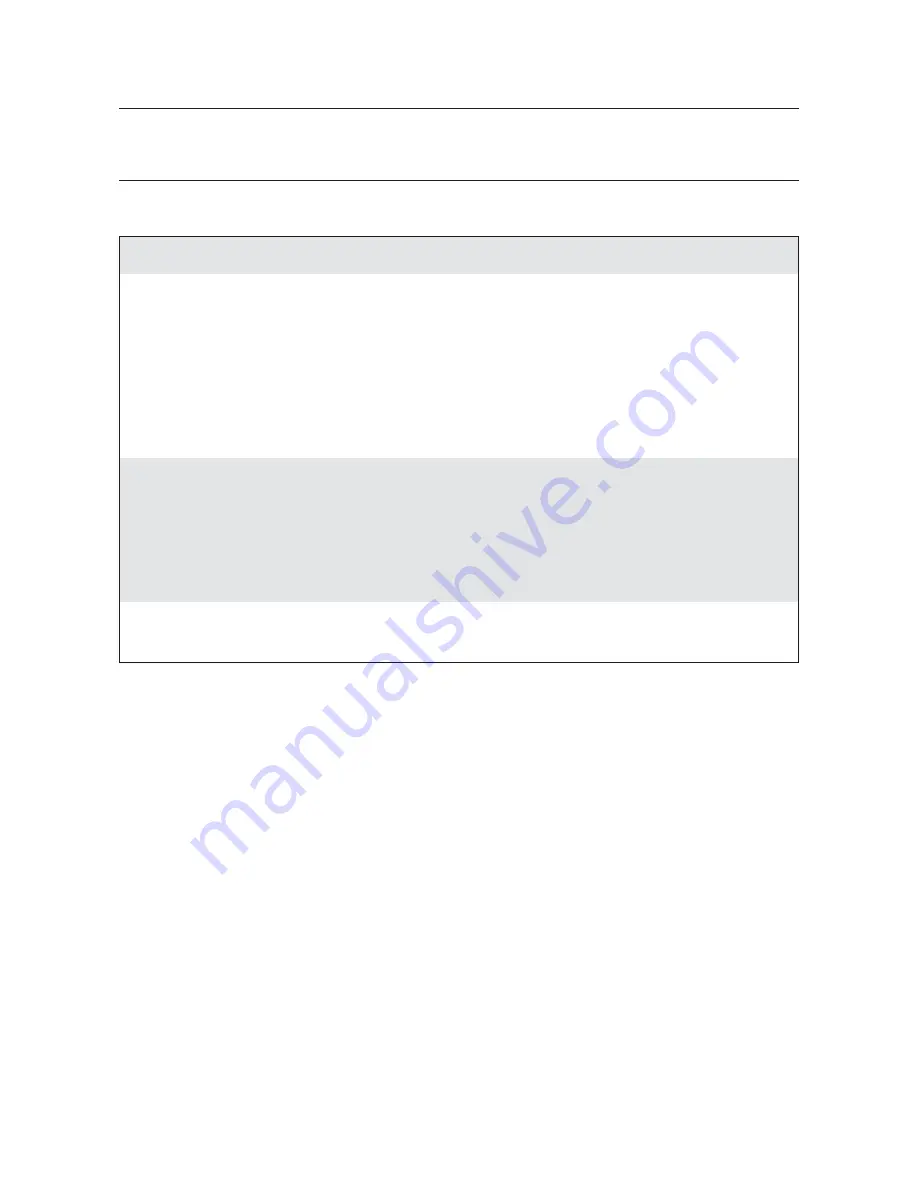

Problem

Cause/result

Repair

The valve does not maintain

- Faulty diaphragm

- Replace the diaphragm

the preset pressure

- Guide (9) seizes

- Lubricate the guide (see section 3.1)

- Incorrect operating range

- Check the pressure drop over the

valve and check the flow rate (see

section 5.2)

- The available air pressure is

- Increase the air pressure eg. by using

lower than the product pressure

a Booster (see section 2.4).

- The air pressure is not correctly

- Readjust the air pressure

adjusted

- Faulty air pressure regulating

- Repair the valve or check that it is

valve or incorrect type

pressure compensating

Product leakage

- Worn diaphragm

Replace the diaphragm

- Product affected diaphragm

Air leakage

- Worn O-ring

- Replace the O-ring

- Worn diaphragm (10)

- Replace the diaphragm

- Worn and hard diaphragm (10)

- Replace by a diaphragm of a different

grade for higher temperature (see

section 5.1)

Valve plug moving too fast

Pressure pulsations because of

Use an air throttling valve (optional extra

up and down (unstable)

fast changes in process conditions

between the air pressure regulating

valve and the CPM-2 valve.

Pay attention to possible break-down.

Study the instructions carefully.

The items refer to the parts list and service kits section.

3.2 Fault finding

NOTE!

Study the maintenance instructions carefully before replacing worn parts - see section 4.1