AIR PURGE AND TEST OPERATION

When Using The vacuum Pump

(For method using a manifold valve, refer to this operation manual.)

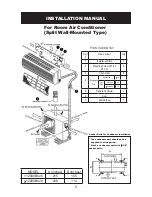

Completely tighten the flare nuts, A, B, C, D, connect the manifold valve

charge hose to a charge port of low-pressure valve on the gas pipe side.

Connect the charged hose connection to the vacuum pump.

Fully open the handle “Lo” of the manifold valve.

Operate the vacuum pump to evacuate. After starting the evacuation,

slightly loosen the flare nut of the “Lo” valve on the gas pipe side and

check that the air is entering. (Operation noise of the vacuum pump

changes and a compound meter indicated 0 instead of minus)

After the evacuation is complete, fully loosen the handle “Lo” of the

manifold valve and stop the operation of the vacuum pump.

Make evacuation for 15 minutes or more and check that the compound

meter indicates -76cmHg(-1.0x10 Pa).

Turn the stem of the packed valve B about 45

o

counter clockwise for 6~7

seconds after the gas comes out, then tighten the flare nut again. Make

sure the pressure display in the pressure indicator is a little higher than

the atmosphere pressure.

Remove the charge hose from the Low pressure charge hose.

Fully open the packed valve stems B and A.

Securely tighten the cap of the packed valve.

i.

ii.

iii.

iv.

v.

vi.

vii.

viii.

ix.

Manifold valve

Compound meter

Pressure gauge

Handle “HI”

Handle “LO”

Charge hose

Charge hose

Vacuum pump

Low pressure valve

-76cmHg

14