END OF YEAR CLEANING AND MAINTENANCE

11

1. Remove the exhaust pipe. Thoroughly clean and

place in a dry location during nonburning months.

Clean exhaust tubes in stove body of all debris.

2. Remove coal from stove and vacuum clean.

3. Thoroughly brush inside of stove body, free of all fly

ash and vacuum clean.

4. Remove the Half Moon Paddle from feed tray,

(loosen

the two setscrews at bottom of paddle allowing feed arm

to drop down).

Pull Paddle out from top of feed tray,

clean shaft, lubricate, and reinstall.

5. Locate grate inside stove, clean all holes.

6. Locate Air Motor Tray. Remove bolt from bottom of

tray, disconnect wiring, and remove air motor tray.

Thoroughly clean motor and plastic combustion

wheel. Vacuum under grate through hole where air

motor tray was removed. Replace air motor tray,

wiring and bolt,

Do Not Over Tighten Bolt!

7. Locate distribution blower. Thoroughly clean motor

and wheel of dust.

8. Inspect all gaskets and replace if necessary.

Note: All gaskets should be replace every three years.

9. Remove top of stove, Thoroughly clean inner top,

replace top.

10. Lightly spray WD-40

inside only

of stove body.

11. Let stove stand for a few minutes. After stove has

ventilated adequately place a low watt lit bulb inside

stove body. This will aid in keeping dampness out

of stove.

NOTE: Important!! If grate has been removed make

sure gaskets are installed properly. See Page 2 Figure 1.

CONTACT YOUR LOCAL BUILDING OR FIRE OFFICIALS ABOUT RESTRICTIONS AND INSTALLATION INSPECTION IN YOUR AREA

Quality Since 1977

STOVE COMPANY

ALASKA COMPANY, INC.

BLOOMSBURG, PA 17815

MODEL: KAST CONSOLE, CHANNING, LIBERTY FUEL COAL SERIAL NO.

U.S. ENVIRONMENTAL PROTECTION AGENCY

THIS HEATER IS ONE FOR BURNING COAL. USE OF ANY OTHER SOLID FUEL EXCEPT FOR COAL IGNITION PURPOSES IS A VIOLATION OF FEDERAL LAW

CONAM Inspection, Inc. Auburn, MA 01501 STL - 002

Tested 2/97 to ANSI/UL, CSA B366-1979 & ETLM 781

CHIMNEY TYPE: MINIMUM 6 INCH DIAMETER APPROVED LOW HEAT RESIDENTIAL TYPE ALL FUEL. CHIMNEY CONNECTOR: 6 INCH DIAMETER 24 GAUGE

BLUE OR BLACK STEEL. INSTALL AT LEAST 4 INCHES FROM WALL AND 6 INCHES FROM CEILING. SPECIAL METHODS ARE REQUIRED WHEN PASSING

THROUGH A WALL OR CEILING. SEE INSTRUCTIONS AND BUILDING CODES. SEE DIAGRAM.

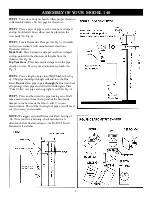

CORNER INSTALLATION

6"

13"

HOPPER

ST

OKER

FRONT

6"

13"

FLOOR PROTECTOR

MINIMUM SIZE

FRONT

16"

USE APPROVED

FLOOR PROTECTOR

HOPPER

STOKER

8"

8"

8"

TOP VENT

HOPPER

STOKER

FRONT

2"

10"

18"

REAR VENT

HOPPER

STOKER

FRONT

4"

18"

INSTALL WITH MINIMUM CLEARANCE

TO WALL AS SHOWN (IN INCHES)