Page 14

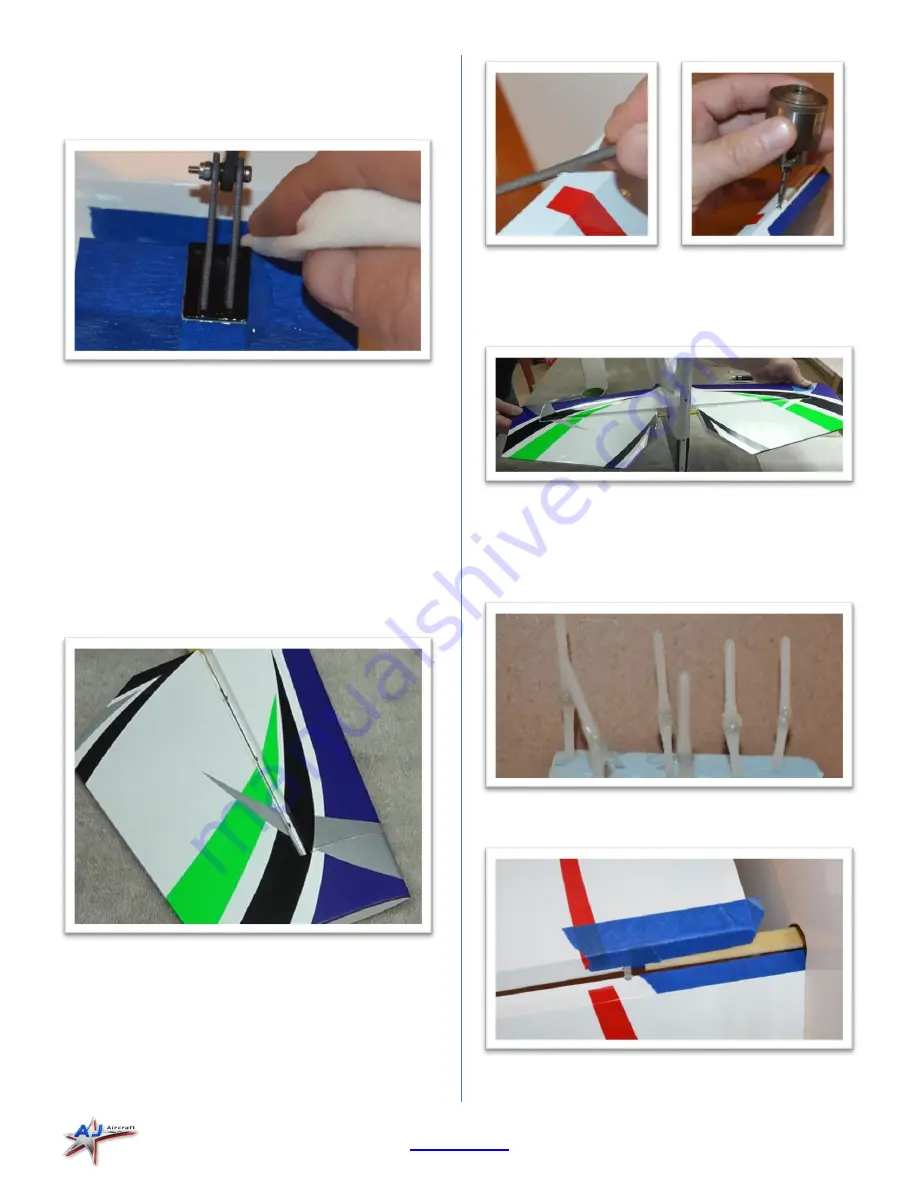

Wipe away excess epoxy using a paper towel soaked with

denatured alcohol. Use an upward rolling motion as you

wipe the excess epoxy to lift it from the surface. This

helps reduce smearing the epoxy.

Check the alignment along the hinge line as you did when

you test fit the control horn. Reposition as needed. Allow

the epoxy to partially cure. Peel away the masking tape

after the epoxy is securely holding the control horn in

place and still soft enough to easily remove the tape. Set

aside and let the epoxy fully cure.

Insert hinge pins into the elevator halves and the

horizontal stabilizer. Test fit pieces together and make

adjustments so you get a good fit between the elevator

and the stabilizer. Check the hinge gap and the gap at the

counter balance.

A small round file can be used to give the hinges some

clearance. Cleaning out the holes will also help you close

up any gap in the hinge line.

Turn a 1/8”

drill into the

holes by hand.

Hold half of the elevator aligned to the leading edge of

the stabilizer and ensure the opposite elevator half is also

aligned at the leading edge. Sand or shim the elevator

joiner plate until both halves are aligned.

Apply petroleum jelly (Vaseline) to the center hinge pin

portion of each hinge. This will help prevent glue from

getting into the hinge when gluing then into the elevator.

Avoid getting petroleum jelly on the barbed portion of

the pin. If you do clean it off with alcohol.

Use painter masking tape to prevent glue from getting

where you don’t want it.