Page 17

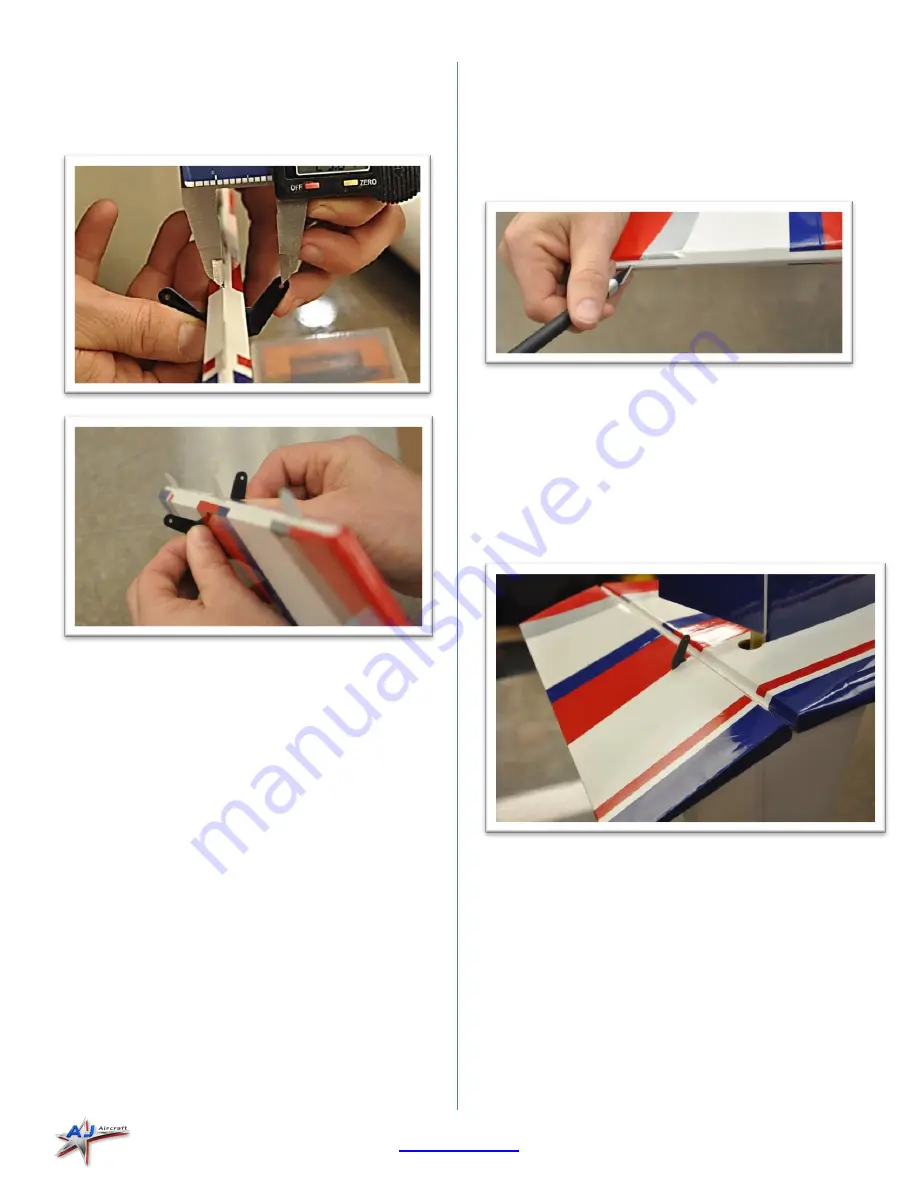

Tests fit the control horn to the slot. Use a file to modify

the slot as needed. Center it side to side and align the

holes with the hinge line. The control horn should be

symmetrical about the hinge line.

Apply masking tape around the control horn slot on both

sides of the rudder.

Use 30 minute epoxy to glue the control horns in place.

Check the alignment, peal the masking tape away, and

clean up with alcohol.

Check the alignment again and set aside for the epoxy to

cure. (When setting aside to dry position the rudder and

control horn so gravity does not reposition the control

horn for you.)

The hinges should already be glued into the rudder. Give

each of them a little pull to ensure they are securely

attached.

The vertical stabilizer is already slotted for the hinges.

Use a covering iron to secure the covering along the edge

of the rudder and stabilizer. Look at the vertical stabilizer

hinge slots closely. Make sure the covering will not

interfere when gluing the hinges. Cut away any covering

that covers the hinge slot.

Slip each rudder hinges into a slot. Align the end of the

rudder with the top of the vertical stabilizer.

Push the rudder tight against the stabilizer closing the

gap between the two of them. Move the rudder to its

maximum desired deflection. (About 15°) Notice how

the hinges may pull out slightly. Experiment with the

hinge position finding the best fit before gluing.

Apply a piece of tape next to each hinge. This will help

you locate the hinges when you begin gluing them.

Start with the top hinge. Flex the rudder slightly and

apply a few drops of thin CA glue to one side.

Flex the rudder to its maximum desired position. Then

glue the opposite side.