© Copyright -

AirApp Power Tools GmbH • Siemensstr. 9 - 11 • 40885 Ratingen

9

V.

INITIAL START-Up

1. Open the air receiver’s drain valve or outlet valve.

2. Plug power supply cord into correct power source.

3. Run the compressor for a minimum of twenty (20) minutes in this no-load condition to lubricate the bearings and pistons.

4. Close air receiver drain valve and outlet valve. Your compressor is ready for use.

VI. MAINTENANCE

Before doing any maintenance or adjustments to your air compressor, the following safety precautions should be taken:

*DISCONNECT ELECTRICAL pOWER.

*DRAIN AIR RECEIVER OF pRESSURE.

pARTS LIST

For assistance in solving the parts problem, we have listed all the parts and components for our air compressors by number.

When replacements are needed, include the model numbers of the compressors, part numbers and required quantity.

If a new assembly is required, include the model of the air compressor undergoing repair(see name place), the part name, part

number, and quantity required, according to the numbers on the parts diagram.

Check List

1.

DAILY OR BEFORE EACH USE:

* Check oil level.

*Drain condensation from air receiver.

*Check for any unusual noise or vibration.

*Be sure all nuts and bolts are tight.

2. WEEKLY:

*Clean air filter by opening air filter, removing filter element and cleaning it thoroughly with soapy water.

*Rinse thoroughly and allow to dry completely before assembly.

*Worn filters should be replaced.

3. MONTHLY:

*Inspect air system for leaks, by applying soapy water to all joints.

*Tighten those joints if leaks are observed.

4.

QUARTERLY OR 300 HOURS (whichever comes first):

*Change compressor oil

*Replace more often if used near paint spraying operations or in dusty, environment.

*

SpECIAL NOTICE !!

ATTENTION:

DURING THE BREAK-IN PERIOD, NUTS & BOLTS MAY LOOSEN UP. PLEASE CHECK.

AFTER TWO WEEKS, TIGHTEN ALL NUTS AND BOLTS, INCLUDING HEAD BOLTS, THEN CHECK EVERYTHING ONCE A

MONTH TO MAKE SURE ALL NUTS & BOLTS STAY TIGHT.

Trouble Shooting

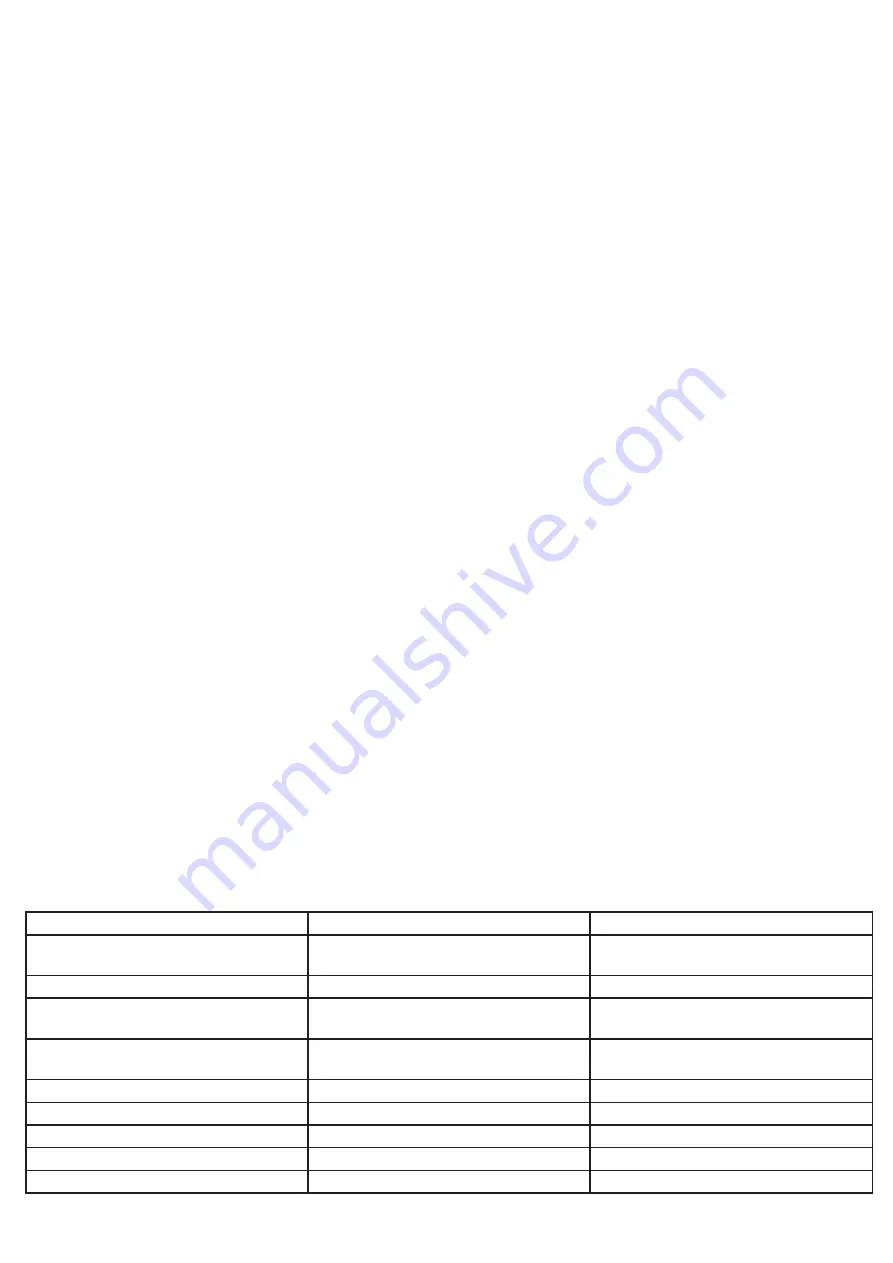

pROBLEM

pOSSIBLE CAUSE

CORRECTIVE ACTION

Will not start

Fuse blown or circuit breaker tripped

Check for cause of blown fuse or brea-

ker and replace or reset.

Loose electrical connections.

Check wiring connections.

Overheated motor.

Press reset button, or wait for automatic

reset.

Low pressure

Air leak in safety valve

Check valve manually If Condition per-

sists, replace valve.

Loose tube or fittings

Tighten fittings.

Restricted air filter

Clean or replace as necessary.

Defective check-valve

Replace check-valve.