© Copyright -

AirApp Power Tools GmbH • Siemensstr. 9 - 11 • 40885 Ratingen

8

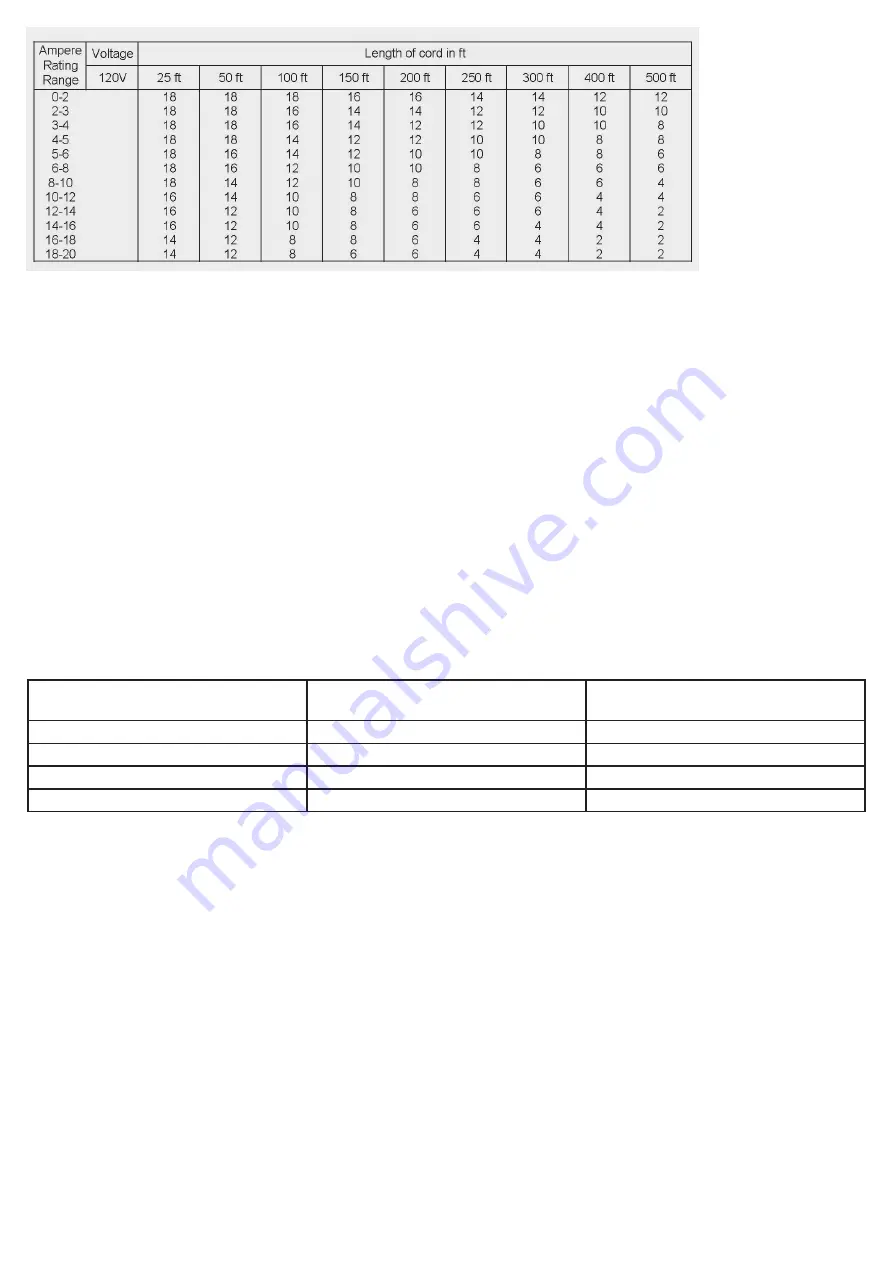

Table 1.1 Minimum gauge for extension cords

III.

COMpRESSOR LUBRICATION

CHECK THE OIL QUANTITY AND QUALITY BEFORE OPERATING THE COMPRESSOR. DO NOT ADD OR CHANGE OIL

WHILE THE COMPRESSOR IS IN OPERATION. USE ONLY THE RECOMMENDED SAE WEIGHT NON-DETERGENT OIL, AS

PER TABLE BELOW.

OIL RECOMMENDATION AND SpECIFICATION

Recommended oil:

The compressor Oil # OIL 10 (1 Liter)

The compressor Oil is a non-detergent mineral oil formulated with additives to help minimize carbon build-up, increase ring

life and reduce oil consumption.

Regular oil changes with the Compressor Oil will increase performance and life expectancy. Manufactured for use at ambient

temperatures of 0 deg. To 30 deg C.

Other approved Oils:

Regular Mineral Oils can also be used in the compressors.

*Always use a non-detergent oil with the following specification:

AMBIENT TEMPERATURES AT POING

OF INSTALLATION

SAE VISCOSITY

ISO VISCOSITY

BELWO -17 DEG.C

SAE 5W

ISO 22

-18 DEG.C TO O DEG.C

SAE 10W

ISO 32

1 DEG.C TO 26 DEG.C

SAE 20W

ISO 68

ABOVE 27 DEG.C

SAE 30W

ISO 100

The lubricant selected must have a pour point of at least 10 deg. C lower than the minimum expected temperature.

FILLING THE OIL

1.

Remove the oil filler plug.

2.

Slowly pour the proper oil into the pump crankcase.

3.

Always keep oil level in the middle of the sight glass.

CHANGING THE OIL

NOTE: EVERY 300 HOURS OR 3 MONTHS WHICHEVER COMES FIRST.

1.

Remove the oil drain plug. Allow oil to drain completely.

2.

Replace the oil drain plug. (The use of a sealing compound or Teflon tape to avoid leakage is recommended).

3.

Refill with the recommended oil to the proper level.

IV.

BEFORE OpERATING THE AIR COMpRESSOR, pLEASE CHECK THE FOLLOWING pOINTS CAREFULLY:

1. Check to see that nuts and bolts are all snug.

2. Check if the quantity and quality of oil is correct (SEE SECTION II. COMPRESSOR LUBRICATION).

3. If the intake filter is dirty, it should be replace, or cleaned.