REFRACTOR PROFESSIONAL OVERDRIVE

19

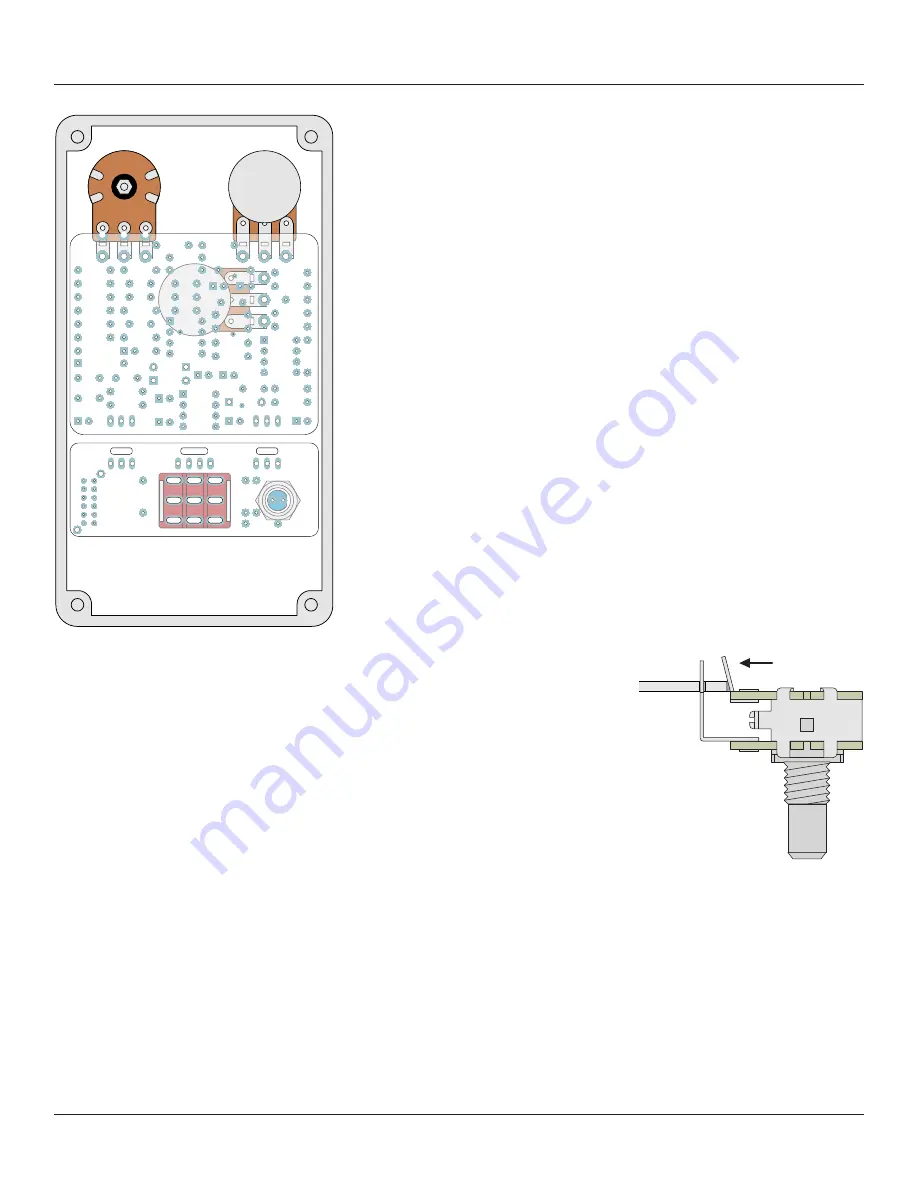

ENCLOSURE LAYOUT: MAIN & FOOTSWITCH PCBS

A note about the dual-gang potentiometer

The upper pads for the dual-gang gain potentiometer appear to be

cut in half.

This is intentional.

It’s called a

plated half-hole

or

castellated

hole

, and it’s used so that the PCB can lay flat across the pots instead of

angling upward for the dual pot.

Solder it like you would if they were normal pads, but bend the top pins

of the pot forward slightly so they make contact with the inside edges of

the half-holes, as shown in the diagram to the right.

Why solder everything inside the enclosure before testing it?

“Rock it before you box it” is conventional wisdom in pedalbuilding, and you’ll often hear it

recommended that builders should test the circuit before putting everything inside the enclosure.

However, Aion FX projects are designed to be extremely easy to remove from the enclosure for

troubleshooting, with no desoldering required—so with these kits, it’s actually much easier to “box it

before you rock it”.

If you’ve read the documentation carefully and followed all the instructions, there’s a good chance you

will get it right the first time!

125B

After all the components are affixed to the enclosure as

shown on the previous page, place the main PCB on top of the

potentiometers as in the diagram to the left.

You may need to adjust the position of the potentiometers

slightly if they are not aligned straight.

Once all of the pins are through and the PCB is laying flat, solder

each of the pins from the top, being careful not to touch any of

the surrounding components with the soldering iron.

After you’ve finished soldering the pots,

clip the leads as close

as you can to the main PCB

. This is more important with the

two uppermost pots because the input/output PCB overlaps

them and you need to avoid any of the components shorting.

Next, do the same thing with the footswitch board—the 3PDT

footswitch and the LED.

Before soldering, double-check to

make sure the flat side of the

LED is facing to the right

, as shown in the diagram, and that the

short leg is coming through the pad on the right. It won’t work if

it’s turned the other way.