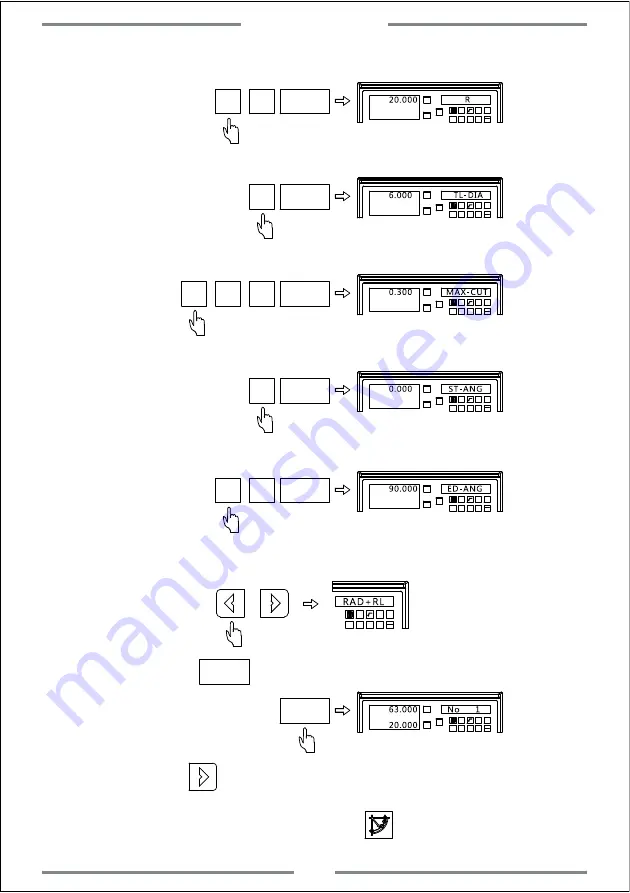

Step 5: Input the arc radius

0

ENT

X

0

Y

0

X

1

3

2

-

+

CLS

Arc

sin

TOOL

2

Step 6: Input the tool diameter

6 ENT

X

0

Y

0

X

1

3

2

-

+

CLS

Arc

sin

TOOL

Step 7: Input the maximum cutting amount

3 ENT

X

0

Y

0

X

1

3

2

-

+

CLS

Arc

sin

TOOL

·

0

Step 8: Input the starting angle

0 ENT

X

0

Y

0

X

1

3

2

-

+

CLS

Arc

sin

TOOL

Step 9: Input the end angle

0

ENT

X

0

Y

0

X

1

3

2

-

+

CLS

Arc

sin

TOOL

9

Step 10: Select the arc plane convex

1

3

2

-

+

CLS

Arc

sin

TOOL

Note:RAD-RL indicates concave

Step 11: Press to enter the machining,and the first point will be

displayed.

ENT

X

0

Y

0

X

1

3

2

-

+

CLS

Arc

sin

TOOL

Step 12: Press to display the following machining point.Move the table

until the value of axis become zero,at this time,the zero point indicates the

exact position for the machining point.Press to exit the smooth R function.

ENT

Special Function

29

Summary of Contents for A20-2V

Page 1: ...LED DIGITAL READOUTS Operation Manual Version 2 0 Driven by Innovation...

Page 2: ...A20 3V Keypad A20 2V Keypad ENT T ENT T E N N T E N N T...

Page 54: ...1 Parameter 2 Dimension 3 Troubleshooting 5 Appendix Appendix...

Page 56: ...5 2 Dimension ENT T T 45 Appendix...

Page 59: ...Driven by Innovation X 0 Y 0 Z 0 X Y Z Operation Manual Version 2 0 DIGITAL READOUTS...