27

GB

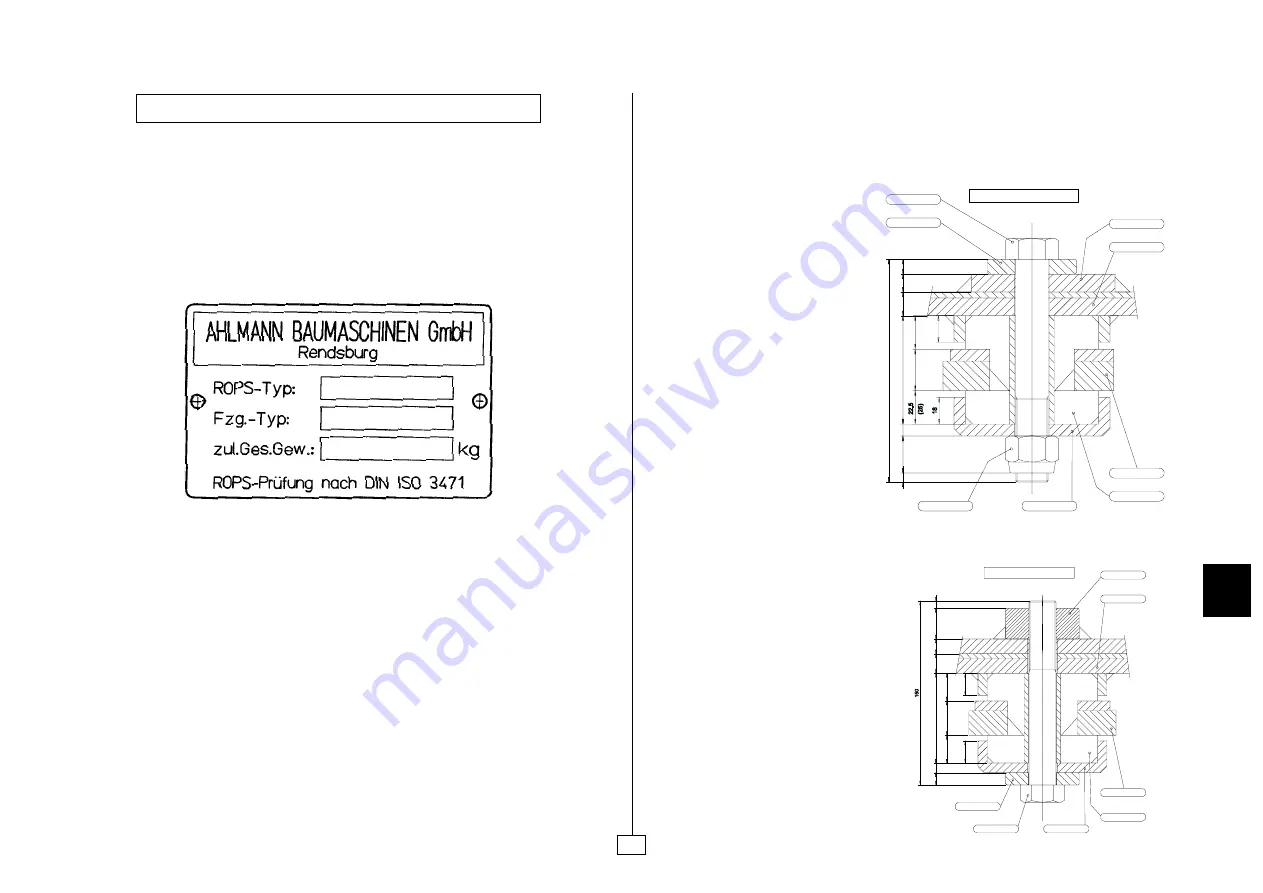

ROPS/FOPS PROTECTION STRUCTURE

1.General Features

The structure is suited to installation only on the vehicle AL 150.

It has been sized for a maximum weight of 11,300 kg. The structure is composed of

uprights with a 4 mm thick plate welded to the top.

The structure is bolted to the frame.

The structure is fastened to the frame as shown in the assembly drawing below:

10

1

2

16

73

8

25

6

15

0

1

8

22

.5

(2

5

)

28

COPPIA DI SERRAGGIO 550 Nm

P/N 000.8.218

P/N 947.0.661

P/N 846.9.731

P/N 847.K.191

P/N 847.K.131

P/N 120.1.024

P/N 947.0.251

P/N 010.4.122

6

2

5

1

2

16

7

3

8

1

0

18

2

2

.5

(2

5

)

2

8

22

.5

(2

5

)

1

8

P/N 846.9.731

P/N 847.K.191

P/N 847.K.131

P/N 120.1.024

P/N 947.0.251

P/N 000.8.218

P/N 947.0.661

COPPIA DI SERRAGGIO 550 Nm

Rear Fasteners

Front Fasteners