40

8210–00009 R1

3. Start the power source and idle at low rpm. Engage hydraulic lever to power winch. Test the direction of

rotation of winch to ensure drum is moving in the direction required. Increase tractor rpm until desired rate

of lift or descent is reached.

Do not touch, grab, or guide cable while equipment is being raised or lowered.

Do not continue to supply power to winch when the conveyor has reached full up position

as this can cause damage.

4. When lowering, if the cable becomes slack before the conveyor is in the full down position, this indicates

that the track shoe is stuck. To correct the problem, reverse the winch and raise the conveyor until the cable

is taut and track slides normally.

5. After lowering, adjust the hydraulic winch until cable has light tension.

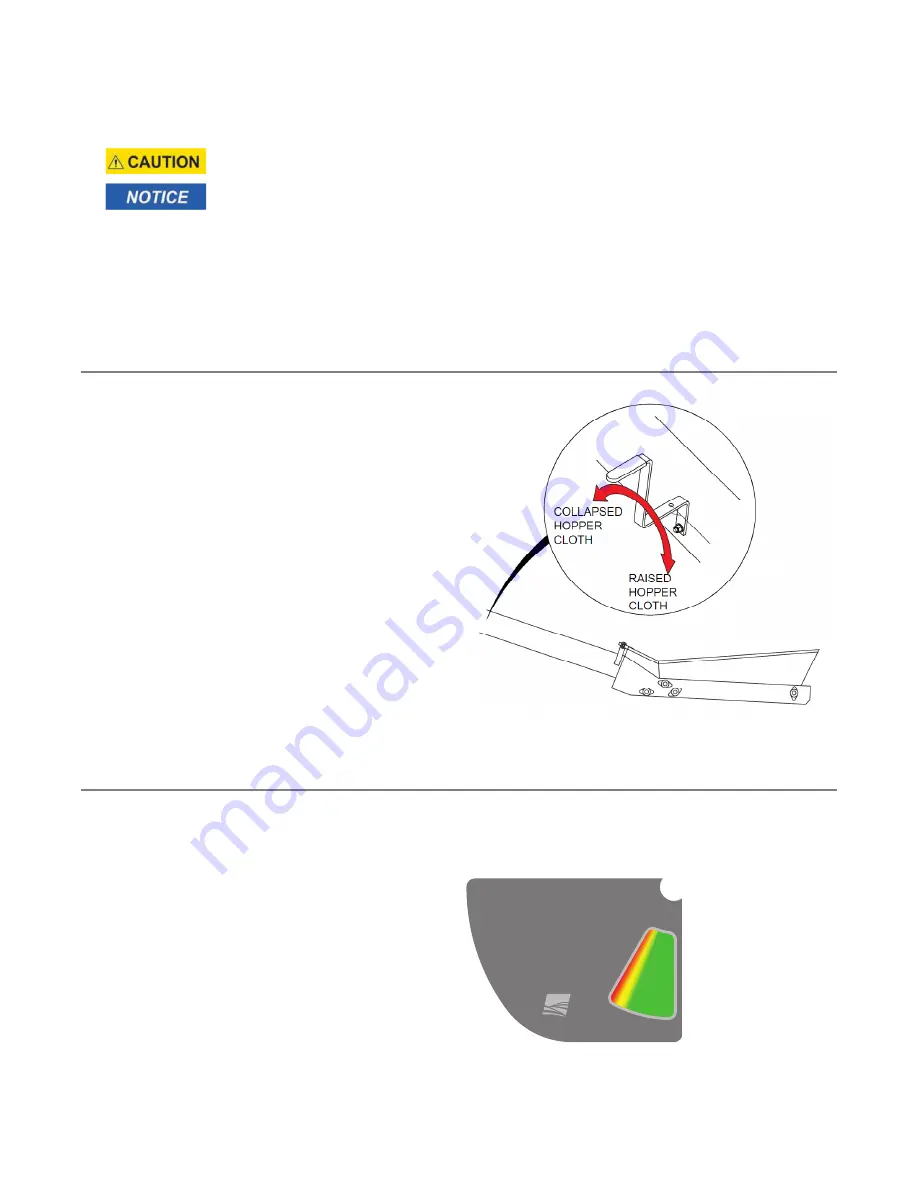

5.6. Collapsible Hopper Cloth Control

The conveyor is designed with a collapsible hopper

cloth to allow it to go under low discharge units.

Move the control handle toward the hopper or intake

to raise the hopper cloth, and move the handle

toward the outlet or spout end to collapse the

hopper cloth.

5.7. Conveyor Operating Angles

Some grains can be moved at steeper angles than others. Grain will roll back if the conveyor is positioned at an

angle greater than the grains natural moving/piling angle (angle of repose). The following table indicates the

maximum angle that different grain types can be moved.

To determine conveyor angle, use the angle guide

decal on your conveyor.

Note

The lower the angle, the greater the capacity

of the conveyor.

If the conveyor is operating

in the yellow or red region,

capacity may be reduced.

Refer to Operator’s Manual.

CONVEYOR ANGLE

S-DRIVE FIELD LOADER – PORTABLE GRAIN BELT CONVEYOR