CAUTION:

Escaping fluid under pressure can penetrate skin causing serious injury. Release pressure

before disconnecting fuel or other lines. Tighten all connections before you apply pressure.

Keep hands and body away from pin holes and nozzles which eject fluids under high

pressure. Use a piece of cardboard or paper to search for leaks. Do not use your hand.

IMPORTANT:

Precaution must be necessary to be sure that the fluids are contained during performance of

inspection, maintenance, test, adjust, and repair. Be prepared to collect the fluid with correct containers

before opening a compartment or you disassemble a component with fluid. Dispose all fluids in accordance

with local regulations and mandates.

NOTE:

Replace the fuel filter elements at 800 hour intervals or if shown by fault code.

IMPORTANT:

The engine warranty is applicable only when original AGCO Power Diesel fuel filter elements

are used.

Procedure

1.

Clean the fuel filters and adjacent area.

2.

Close the fuel valve (5).

3.

Drain prefilter (2).

4.

Disconnect prefilter water detector

connector (1).

5.

Turn filter element (2) counterclockwise and

remove element from the bracket. Collect

fuel into a applicable container.

6.

Remove the water detector (3) from the

prefilter bottom end.

4

5

2

1

3

TREJA0110063201

GUID-BA2EEB53-E1B3-4D3B-9F43-16A638AB01F2-high.eps [High]

Fig. 3

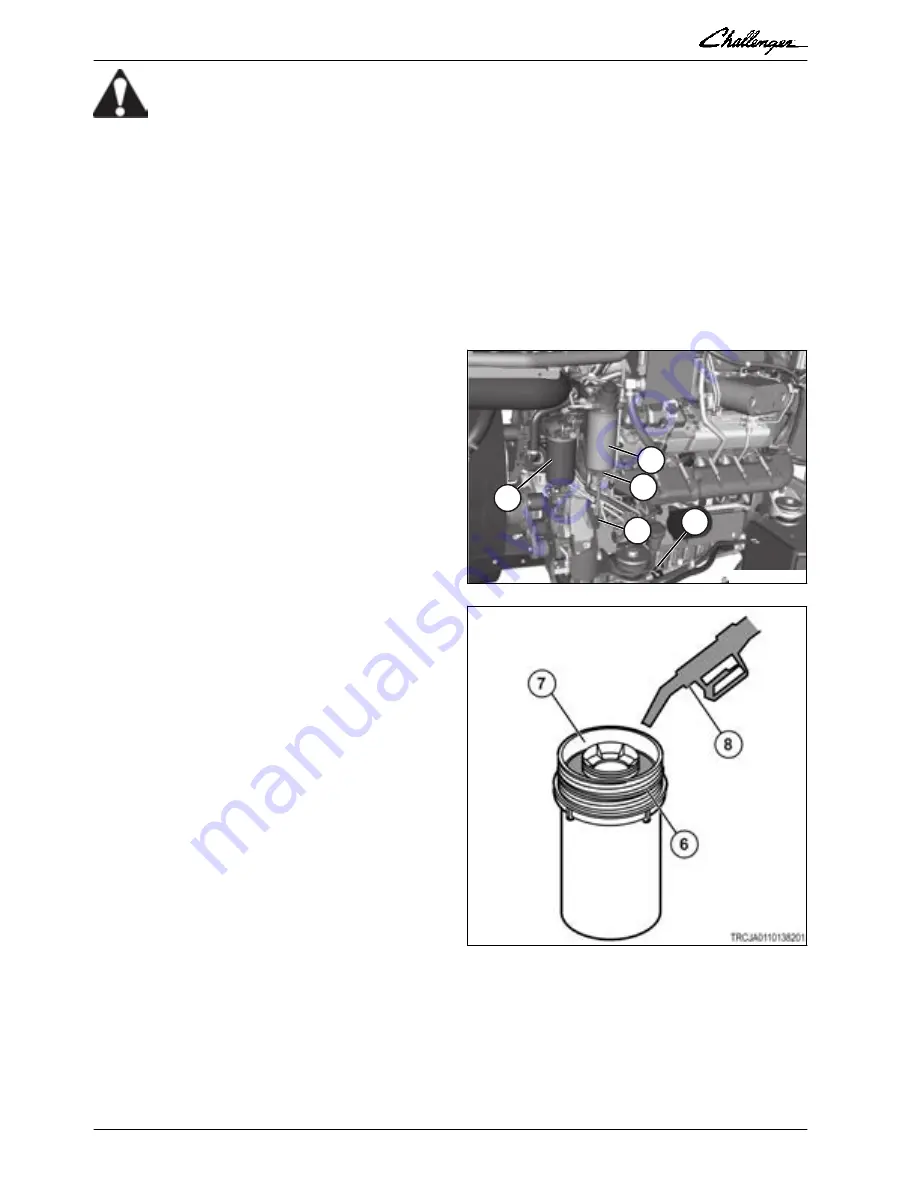

7.

Remove the primary filter (4) in an equivalent

procedure.

8.

Connect the water detector (3) to the new

prefilter bottom end.

9.

Lubricate the filter element o-ring seal (6)

with clean fuel.

10.

Fill the outer shell of the filter element (7)

with clean fuel (8).

11.

Turn filter element on the bracket.

12.

Connect the water detector connector (1).

13.

The primary filter (4) is assembled in an

equivalent procedure.

14.

Open the fuel valve

15.

Prime the fuel system.

16.

Start the engine and make sure there are no

leaks.

GUID-764AE0F5-6EA1-4F5A-8ABD-EBA65A7A4869-high.jpg [High]

Fig. 4

Related Links

page 1-22

2. Engine, fuel, and exhaust system

2-8

Rubber Track Tractor

79036240F