6

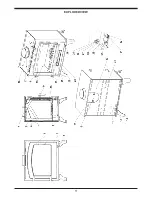

STOVE DIMENSIONS

Fig 3

TECHNICAL DATA

Fuel

Wood

Nominal Output - Room

7kW

Typical refuelling intervals to

obtain nominal outputs

1 hour

Flue Gas Mass Flow

6.7 g/s

Flue Gas temp at Nominal Output

281

o

C

Gross Weight:

105kgs

Flue Outlet:

150mm

Log Size:

330mm

This appliance has been tested in accordance with BS EN

13240

NOTE:-

A suitable chimney (minimum profile, chimney draft, tightness, etc) is a basic condition for the

proper functioning of fireplace stoves. See professional advice before installing the stove.

Chimney values are included in the attached technical sheet. A smoke shutter or a draft regulator

should be installed for chimneys with too strong a draft. Such a draft can cause problems during

operation, e.g. intensive burning, high fuel consumption and can also lead to permanent damage to

the stove.

Summary of Contents for Shawbury

Page 12: ...11 EXPLODED VIEW...

Page 14: ...13...

Page 15: ...14...

Page 16: ...AGA Station Road Ketley Telford Shropshire TF1 5AQ UK Rev 001 DP261114 N00642AXX 15...