INSTALLATION & OPERATING INSTRUCTIONS

GENERAL

When installing, operating and maintaining your

stove respect basic standards of fire safety. Read

these instructions carefully before commencing the

installation. Failure to do so may result in damage to

persons or property. Save these instructions for

future reference.

Special care must be taken when installing the stove

such that the requirements of the Health & Safety at

Work Act are met.

Any alteration that is not approved by AGA, could

invalidate the approval of the appliance, operation of

the warranty and could also affect your statutory

rights. Use only authorised replacement parts.

Handling

Adequate facilities must be available for loading,

unloading and site handling.

Fire Cement

Some types of fire cement are caustic and should

not be allowed to come into contact with the skin. In

case of contact with the skin wash immediately with

plenty of water.

Asbestos

This stove contains no asbestos. If there is a possi-

bility of disturbing any asbestos in the course of

installation then please seek guidance and use

appropriate protective equipment.

Metal Parts

When installing or servicing this stove care should

be taken to avoid the possibility of personal injury.

THE CLEAN AIR ACT 1993 AND SMOKE

CONTROL AREAS

The Clean Air Act 1993 and Smoke Control Areas”

Under the Clean Air Act local authorities may

declare the whole or part of the district of the author-

ity to be a smoke control area. It is an offence to emit

smoke from a chimney of a building, from a furnace

or from any fixed boiler if located in a designated

smoke control area. It is also an offence to acquire

an "unauthorised fuel" for use within a smoke control

2

NOTE:

Please note that it is a legal requirement

under England & Wales Building Regulations that

the installation of the stove is either carried out

under Local Authority Building Control approval or

is installed by a Competent Person registered with

a Government approved Competent Persons

Scheme. HETAS Ltd operate such a Scheme and

a listing of their Registered Competent Persons

can be found on their website at www.hetas.co.uk.

The installation must be completed in

accordance with current National and

European Standards and Local Codes. It

should be noted that the requirements and

these publications may be superseded during

the life of this manual.

IMPORTANT WARNING: This stove must not be

installed into a chimney that serves any other

heating appliance. There must not be an extrac-

tor fan fitted in the same room as the stove as

this can cause the stove to emit fumes into the

room.

area unless it is used in an "exempt" appliance

("exempted" from the controls which generally apply

in the smoke control area).

The Secretary of State for Environment, Food and

Rural Affairs has powers under the Act to authorise

smokeless fuels or exempt appliances for use in

smoke control areas in England. In Scotland and

Wales this power rests with Ministers in the

devolved administrations for those countries.

Separate legislation, the Clean Air (Northern Ireland)

Order 1981, applies in Northern Ireland. Therefore it

is a requirement that fuels burnt or obtained for use

in smoke control areas have been "authorised" in

Regulations and that appliances used to burn solid

fuel in those areas (other than "authorised" fuels)

have been exempted by an Order made and signed

by the Secretary of State or Minister in the devolved

administrations.

Further information on the requirements of the Clean

Air Act can be found here :

http://smokecontrol.defra.gov.uk/

Your local authority is responsible for implementing

the Clean Air Act 1993 including designation and

supervision of smoke control areas and you can

contact them for details of Clean Air Act require-

ments”

The Shawbury stove has been recommeded for use

in smoke controlled areas when burning wood logs

only and fitted with a factory modified air control to

allow a minimum amount of combustion air when the

air controls are set at minimum.

Summary of Contents for Shawbury

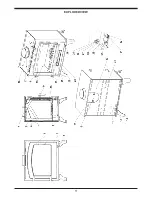

Page 12: ...11 EXPLODED VIEW...

Page 14: ...13...

Page 15: ...14...

Page 16: ...AGA Station Road Ketley Telford Shropshire TF1 5AQ UK Rev 001 DP261114 N00642AXX 15...