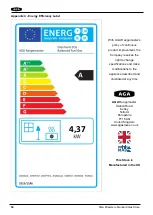

GB & IE

AGA Ellesmere Standard Gas Stove

37

3.7 Commissioning the Appliance

3.7.1 Pilot Ignition Check

1. Ignite the pilot light as described in the User Instructions

2. Check that the pilot flame stays alight

3. Extinguish the pilot light

3.7.2 Main Burner Check

1. Ignite the pilot light as described in the User Instructions

2. Turn on the main burner as described in the User Instructions

3. Check that the pilot smoothly cross-lights to the burner and that the main burner & pilot stay alight

4. Extinguish the appliance fully

3.7.3 Pressure Check

The appliance is pre-set to give the correct heat inputs as listed in the technical details. No

further adjustment is necessary. Always check the inlet pressure and burner on hot and cold

pressure. DO NOT ATTEMPT TO ADJUST THE PRESSURES ON THE VALVE THIS WILL VOID

YOUR WARRANTY

1. Turn off the gas valve on the appliance

2. Release the screw on the Inlet Pressure test point on the gas valve and connect a manometer

3. Check that the measured pressure is as the prescribed supply pressure

4. Perform the test when the appliance is burning on full (High Flame) and with only the pilot alight

5. If the pressure is low, check the gas supply pipes are to a correct sizing

6. If the pressure is too high (more than 5 mbar over) the appliance may be installed, but the gas supply

company should be contacted

7. Release the screw on the Burner Pressure test point on the gas valve and connect a manometer

8. Check that the measured pressure is as detailed in the Technical details

9. The measured value should be /- 5% of the described value. If this is not the case, please

contact the supplier.

Note: After checking the pressures and removing the manometers, the screws in the Pressure Test

points must be closed, and the system must be checked for gas-tightness.

Pressure Check

– It is important to carry out a

pressure check on the appliance. There are 2 test

points on the side of the valve. The first is the

Inlet Pressure

, the second is

Outlet/Burner

Pressure.

These screws need to be

“opened” (approx 1 turn

but not removed) before putting the tube of the

manometer on. Both these screws must be fully

tighten (“closed”) when the manometer is

removed. Shown on your picture as Inlet and

Outlet Pressure Tap.

When opening these test points the room must be well ventilated and no naked flames or sparks are to

be near the stove. You must fully leak test the valve after commissioning