3.1. Preventative Maintenance

Do an inspection of the GL4 and the external wiring one time each month. It might be necessary to do

more frequent inspections based on:

l

The operating conditions of the system.

l

How you use the system.

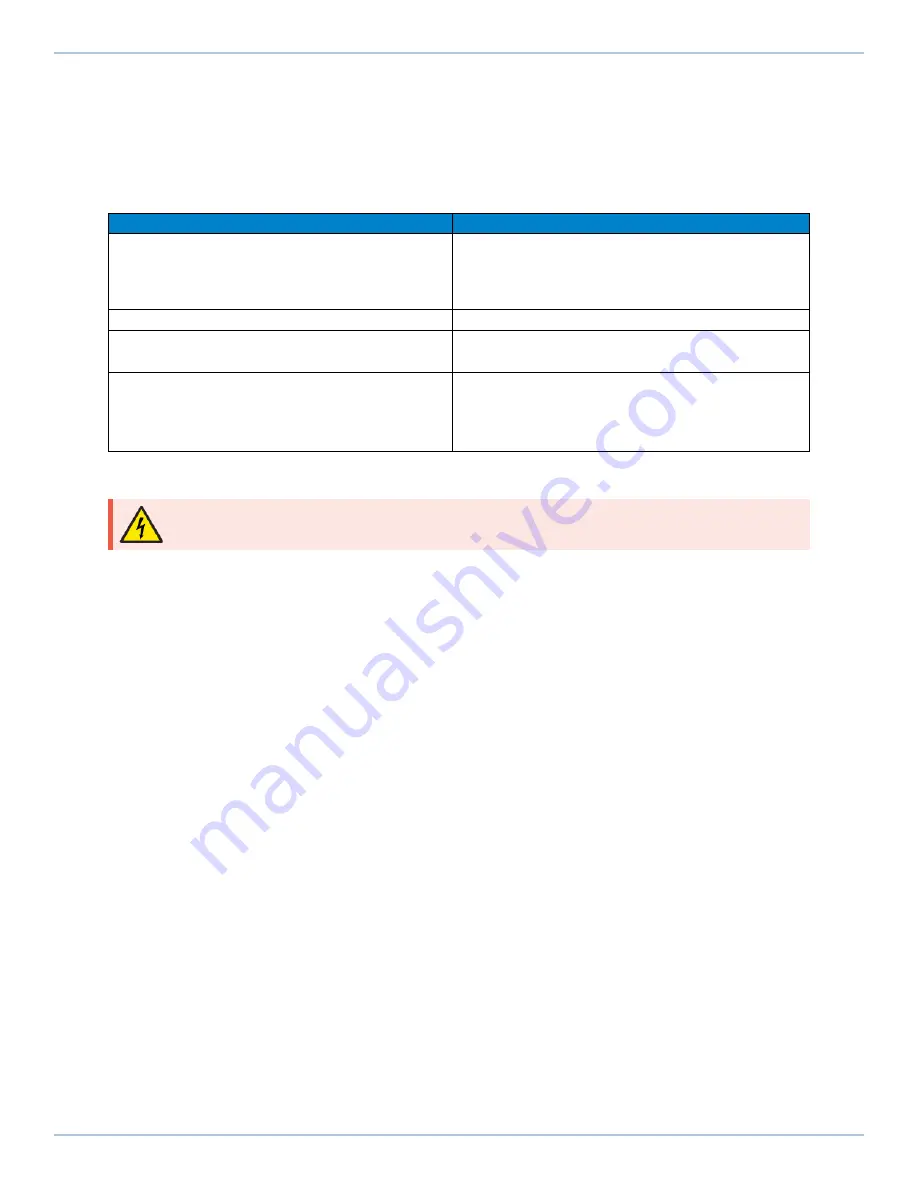

Table 3-3:

Preventative Maintenance

Check

Action to be Taken

Examine the chassis for hardware and parts that

are damaged or loose.

It is not necessary to do an internal inspection

unless you think internal damage occurred.

Repair all damaged parts.

Do an inspection of the cooling vents.

Remove all material that collected in the vents.

Examine the work area to make sure there are no

fluids and no electrically conductive materials.

Do not let fluids and electrically conductive material

go into the drive.

Examine all cables and connections to make sure

they are correct.

Make sure that all connections are correctly

attached and not loose.

Replace cables that are worn.

Replace all broken connectors.

Cleaning

DANGER

: Before you clean the GL4, disconnect the electrical power from the drive.

Use a clean, dry, soft cloth to clean the chassis of the drive. If necessary, you can use a cloth that is moist

with water or isopropyl alcohol. If you use a moist cloth, make sure that moisture does not go into the

drive. Also make sure that it does not go onto the outer connectors and components.

Do not use fluids and sprays to clean the drive because they can easily go into the chassis or onto the

outer connectors and components. If a cleaning solution goes into the drive, internal contamination can

cause corrosion and electrical short circuits.

Do not clean the labels with a cleaning solution because it might remove the label information.

3.1. Preventative Maintenance

GL4 Hardware Manual

58

www.aerotech.com