9

Aermec cod. 14.09 4086982_03

NRL 2000-3600 60Hz

EN

5.

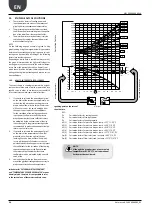

DESCRIPTION OF COMPONENTS

5.1.

CHILLER CIRCUIT

SCROLL COMPRESSORS

High efficiency scroll-type hermetic compressors, as-

sembled on elastic antivibration supports, driven by a

2-pole electric motor with internal thermal protection.

of the electric heater casing included as standard. The

heater is automatically powered when the unit stops,

provided that the unit is kept under tension.

WATER SIDE HEAT EXCHANGER

Of the plate-type (AISI 316), externally insulated with

closed cell material to reduce thermal dispersion.

Fitted, as standard, with antifreeze heater.

5.1.1.

WATER FEATURES

SOURCE SIDE HEAT EXCHANGER

Made with copper pipes and aluminium louvered fins

blocked by mechanical expansion of the pipes. Provi-

ded with protective grid.

DESUPERHEATER / TOTAL RECOVERY

Unit with (AISI 316) heat plate, insulated externally

with closed cell material to reduce heat loss.

CYCLE INVERSION VALVE

(ONLY HEAT PUMP VERSION)

4way cycle inversion valve. Inverts the flow of refrige-

rant gas.

LIQUID STORAGE TANK

(ONLY HEAT PUMP VERSION/TOTAL RECOVERY)

Compensates the difference in volume between louve-

res coil and plate exchanger, withholding excess liquid.

DEHYDRATOR FILTER

Hermetic-mechanical with cartridges made of ceramic

and hygroscopic material, able to withhold impurities

and any traces of humidity present in the cooling

circuit.

ONE-WAY VALVES

Allows the passage of the refrigerant in just one

direction.

MECHANICAL THERMOSTATIC VALVE

The mechanical valve, with external equaliser positio-

ned at the evaporator inlet, modulates the flow of gas

to the evaporator, according to the heat load, in order

to ensure a correct heating level of the intake gas.

SOLENOID VALVE

The valve closes when the compressor turns off,

preventing the flow of refrigerant gas towards the

evaporator.

INDICATOR FOR LIQUID PASSAGE WITH HUMIDITY

PRESENCE SIGNAL

Used to check the refrigerant gas load and the eventual

presence of humidity in the cooling circuit.

LIQUID AND PRESSING LINE TAPS

(ONLY COOLING VERSION)

Allows interruption of the refrigerant in the case of

extraordinary maintenance

.

LIQUID SEPARATOR

(ONLY HEAT PUMP VERSION)

Located on the suction point of the compressor, to pro-

tect against any flowback of liquid refrigerant, flooded

start-ups, operation in the presence of liquid.

BY PASS SOLENOIDE VALVE

(ONLY HEATING RECOVERY VERSION)

By-passes the thermostatic valve during the defrosting

cycle.

5.2.

FRAME AND FANS

SUPPORT FRAME

Load-bearing structure Made of hot-galvanised steel

sheet of a suitable thickness, varnished with polyester

powders able to resist atmospheric agents over time.

VENTILATION UNIT

Axial fan, balanced statically and dynamically. The elec-

tric fans are protected electrically by magnet-circuit

breakers and mechanically by anti-intrusion metal

grids, according to the IEC EN 60335-2-40 Standard.

5.3.

HYDRAULIC CIRCUIT STANDARD COM

-

PONENTS

FLOW SWITCH

It checks that there is circulation of water.If

this is not the case, it blocks the unit

WATER TEMPERATURE PROBE (IN-OUT)

AIR VENT

Of the automatic type, assembled on the upper part of

the hydraulic system; it releases any air bubbles that

may be present in the system.

DRAIN TAP

5.4.

HYDRAULIC COMPONENTS FOR CONFI

-

GURABLE VERSIONS

CIRCULATION PUMP

(HIGH/LOW PUMP)

Depending on the characteristics of the pump chosen,

it offers a useful head to overcome the pressure drops

in the system.

EXPANSION TANK

(STANDARD SUPPLY TO PUMP AND STORAGE TANK

VERSION)

With nitrogen pre-load membrane.

SAFETY VALVE

Equipped with a piped discharger and intervenes by

discharges the over pressure in case of anomalous

pressures.

STORAGE TANK

In order to reduce the thermal dispersion and elimina-

te the phenomenon of the formation of condensation,

it is insulated with polyurethane material of a suitable

thickness. It is required to reduce the number of peaks

of the compressor and to even the temperature of

water to be sent to the utilities.

STORAGE TANK DRAIN TAP

WATER FILTER

Equipped with steel filtering mesh; prevents the heat

exchangers from clogging.

5.5.

SAFETY AND CONTROL COMPONENTS

HIGH PRESSURE SWITCH (MANUAL RESET)

With fixed calibration, placed on high pressure side of

cooling circuit, inhibits functioning of compressor if

abnormal work pressure occurs.

HIGH PRESSURE TRANSDUCER

Placed on high pressure side of cooling circuit, signals

the work pressure to control board, generating a pre-

warning in case abnormal pressure occurs.

LOW PRESSURE TRANSDUCER

Allows displaying, on the microprocessor board display,

the value of the compressor's suction pressure (one

per circuit) on the low-pressure side of the cooling

circuit

SAFETY VALVE

Equipped with a piped discharger and intervenes by

discharges the over pressure in case of anomalous

pressures.

- Set at 45 bar on the branch HP

- Set at 30 bar on the branch LP

LOW PRESSURE SWITCH

5.6.

ELECTRICAL PANEL CONTROL AND

POWER

Electric board in compliance with standards EN 60204-

1/IEC 204-1, complete with:

- door lock main isolating switch,

- fuses and contactors for compressors and fans,

- terminals for REMOTE PANEL,

- spring type control circuit terminal board,

- outdoor electric board with double door and

gaskets,

PH

6-8

Electric

conductivity

less than 200 mV/cm

(77°F / 25°C)

Chloride ions

less than 50 ppm

Sulphuric acid ions

less than 50 ppm

Total iron

less than 0.3 ppm

Alkalinity M

less than 50 ppm

Total hardness

less than 50 ppm

Sulphur ions

none

ammonia ions

none

Silicone ions

less than 30 ppm