Condensate Neutralization Tank User Instructions

TID-0074_0H

•

8/22/2022 Technical Support

•

(800) 526-0288

•

Mon-Fri, 8 am - 5 pm EST Page

4

of

14

TABLE 3: Neutralizer Tank Application Chart (MFC Series)

AERCO Equipment

BTU/Hr. Input

Kit Qty Required

Two (2) MFC 3000

6,000,000

1

One (1) MFC 4000

4,000,000

1

One (1) MFC 5000

5,000,000

1

One (1) MFC 6000

6,000,000

1

One (1) MFC 8000

8,000,000

2**

One (1) MFC 10000

10,000,000

2**

** Neutralizer tanks are to be installed in parallel. Do not install multiple neutralizer tanks in series.

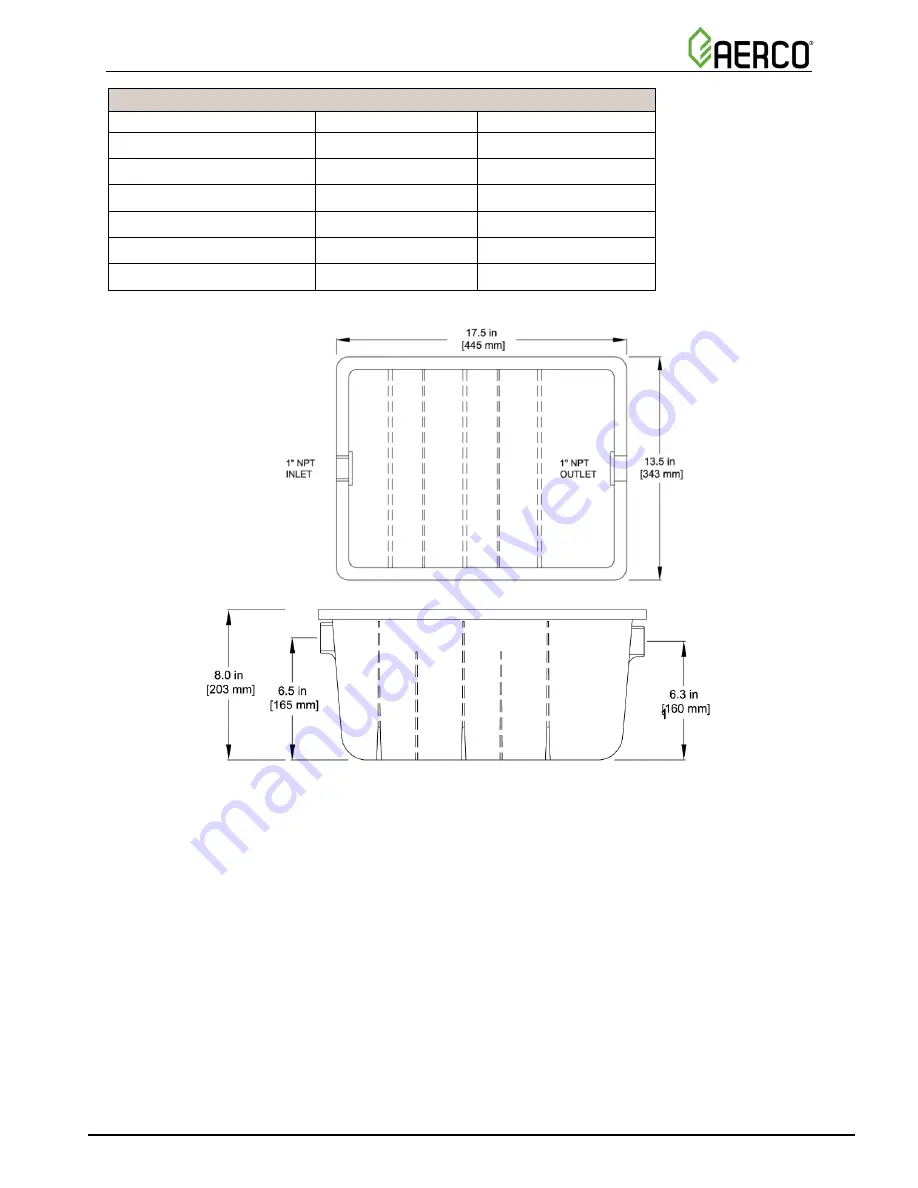

Figure 1: Condensate Neutralization Tank (P/N 89030) Dimensions

The inlet connection (6.5") is higher than the outlet connection (6.3"). Set the neutralization tank

on a secure and level base. Connections to the appliance and neutralization kit must be installed

to ensure that no condensate backflow can occur. Connect appliance condensate drain to the

inlet using corrosion resistant piping. Do not route the condensate line through any area that is

exposed to freezing temperatures. If traffic poses a risk, install some protection to prevent

movement and/or damage. Mount as per installation diagram. Ensure that no air pockets will

remain or form in the piping and that the condensate will flow freely from the appliance condensate

drain into the tank and then to the drain. Access to the discharge is necessary for proper

maintenance in order to check the effectiveness of the neutralizing media, using pH test strips.

If there is no gravity drain available or if the boiler/water heater cannot be elevated to be higher

than the Neutralization Tank, install a condensate removal pump designed for use on condensing

boilers and furnaces (Figure 4).