AEM Performance Electronics

Phone (8am-5pm M-F PST): 310-484-2322

2205 W 126

th

Street, Unit A

Fax: 310-484-0152

Hawthorne, CA 90250

Hardware Overview

AEM Part Number

30-8000

Microprocessor

NXP MPC5607B

Clock Speed

64 MHz

Environmental

IP6k7 Compliant

Operating Temperature

-40°C to +105°C

Operating Voltage

9 – 16V

16V is the absolute maximum rating.

The module is not designed for use

with 16V battery systems as they typically require ~18V to charge.

Overvoltage Protection

16V

Current Draw: Off-State Current

<1 mA

Wake Switch Power-on threshold

3.7V minimum

Wake Switch Power-down threshold

1.5V maximum

Communication Channels

CAN1, 500k, Internally Terminated, PC Comms

CAN2, 500k, Internally Terminated, Peripheral Device Comms

CAN3, 500k, Internally Terminated, Peripheral Device Comms and Data

Transmit

CAN4, RESERVED

Internal Logging Memory

None

- External logging possible with AEM Dash units with logging

capability and other compatible 3

rd

party displays and data loggers.

About this document

This document is not a comprehensive step by step guide to every feature available. It is intended to get the VCU

powered up properly and running quickly in a bench top environment. Along the way you will become familiar with

certain core features. Your primary source for detailed information about VCU functionality is AEMCal. Nearly all

features are described using tool tips, compiled help or description pane help. The AEMCal screen capture images in this

document are accurate at the time of publication. However, AEMCal and the AEMCal layout files provided by AEM will

be updated over time. In the event of a discrepancy, always follow the instructions contained within the layout file.

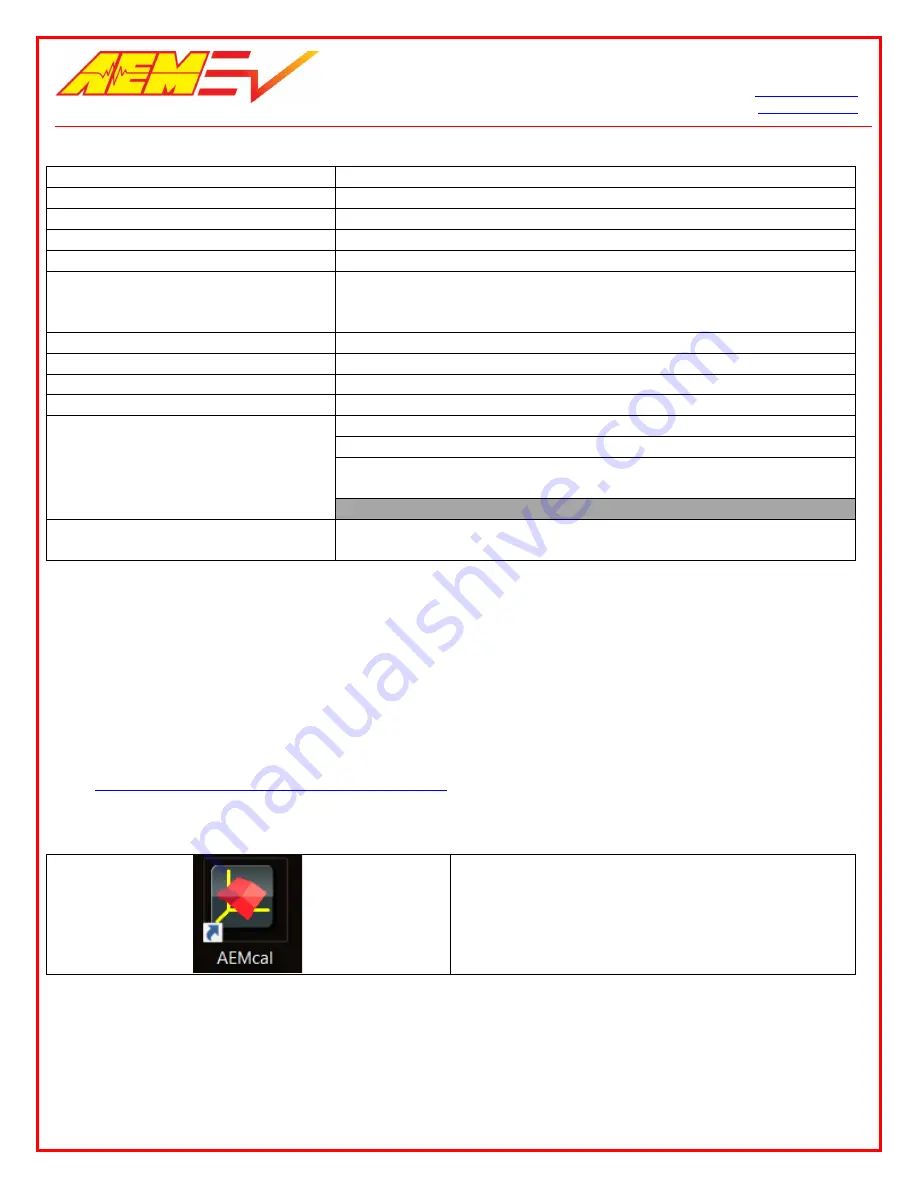

Software Tools Installation

Go to

https://www.aemev.com/documentation/download

to download the installers for AEMCal and AEMData. Run

both installers to install both tools. During the installation, choose to install the desktop icon. After the installation,

restart your PC.

Launch AEMCal from the desktop icon.

6/3/2020, Revision C

AEM EV VCU200 User Guide

Page

4

of

15