INPUT CHANNEL OVERVIEW

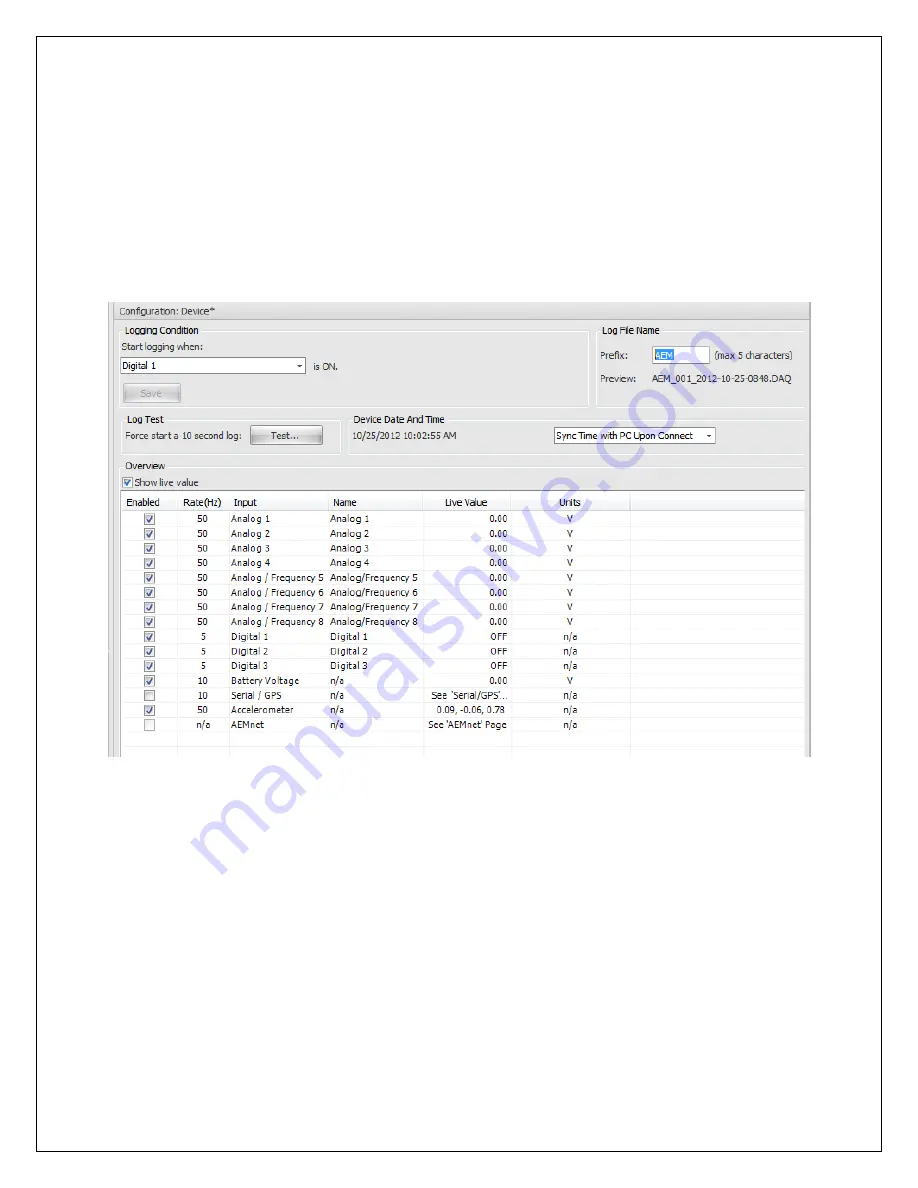

The input channel overview page shows an overview of the input channels and is used

for setting the logging condition, as well as naming log files. The Logging Condition

determines when the AQ1 Data Logger starts logging. In the example below, the AQ1

Data Logger will start logging when digital input 1 is turned on (grounded). Input

channels are enabled/disabled with the check box in the enabled column. The Sync

with PC button is used to sync the internal AQ1 Data Logger clock with the PC clock or

a GPS. The internal AQ1 Data Logger clock is used for the time stamp on log files.

The clock must be re sync’d after perm power has been removed. See Figure 10

below.

ANALOG 1-4 INPUTS

The pages for analog 1-4 are used to configure the analog 1-4 inputs, as well as show

live data for easy setup and troubleshooting. Channels are enabled by the enabled

check box. Both calibrated and raw (non-calibrated) live data are shown in the Live

Data section. The sample rate is selected in the Sample Rate box. Users are able to

name channels in the Name window. The optional 2200 ohm pullup resistor is enabled

by the Enable 2200 Ohm pull-up resistor check box. The 2200 ohm pullup resistor

should only be enabled when an input from an RTD or Thermistor type temp sensor is

being used. Sensors are selected by clicking on the browse button in the Wizard Name

box. A graph and table of the sensor calibration data are also shown at the bottom of

the page. The units can be changed by clicking on the browse button in the Units box.

Figure 11 below shows Analog 1 configured for a GM style water temp sensor. Figure

12 below shows the GM style water temp sensor in the sensor wizard.

Figure 10. Input Channel Overview Page