A drill template for the AQ1 Data Logger is provided on the last page of the instruction

manual. Drill the four mounting holes with a 3/16

” drill bit. With the dust cover on the

AQ1 Data Logger module, secure the module using the supplied 6-

32 x 1 ¼” stainless

screws and nuts. Some resistance will be felt when inserting the mounting screws for

the first time as the screws will pierce the dust cover. A sharp pick or paper clip can be

used to make pilot holes in the dust cover if desired.

Note: the dust cover is made of

a specially selected material that allows the cover to be flexible, yet does not rip

or tear.

WIRING

Power Connections

RED (PERM PWR)- Connect to a fused (5 Amp) constant 12 volt power source.

RED (SWIGN)

– Connect to a fused (5 Amp) switched 12 volt power source.

BLACK (BATT GND)

– Connect to a clean power ground. (Do not connect to a sensor

ground)

AEMnet

AEMnet is an open architecture software and hardware interface based on the CAN 2.0

specification, which provides the ability for multiple enabled devices to easily

communicate with each other through a single cable. The hardware connection is made

through a Deutsch 4P DTM connector and contains 12 volt switched power and ground

(2A max) as well as the CAN data lines. Devices connected to the AEMnet transmit

data through this one connection and most of these devices receive power from this

same connection as well.

The following AEM products are currently AEMnet enabled:

Series 2 Engine Management System

EMS-4 Universal Standalone Engine Management System

4-Channel Wideband UEGO Controller

AQ-1 Data Logger

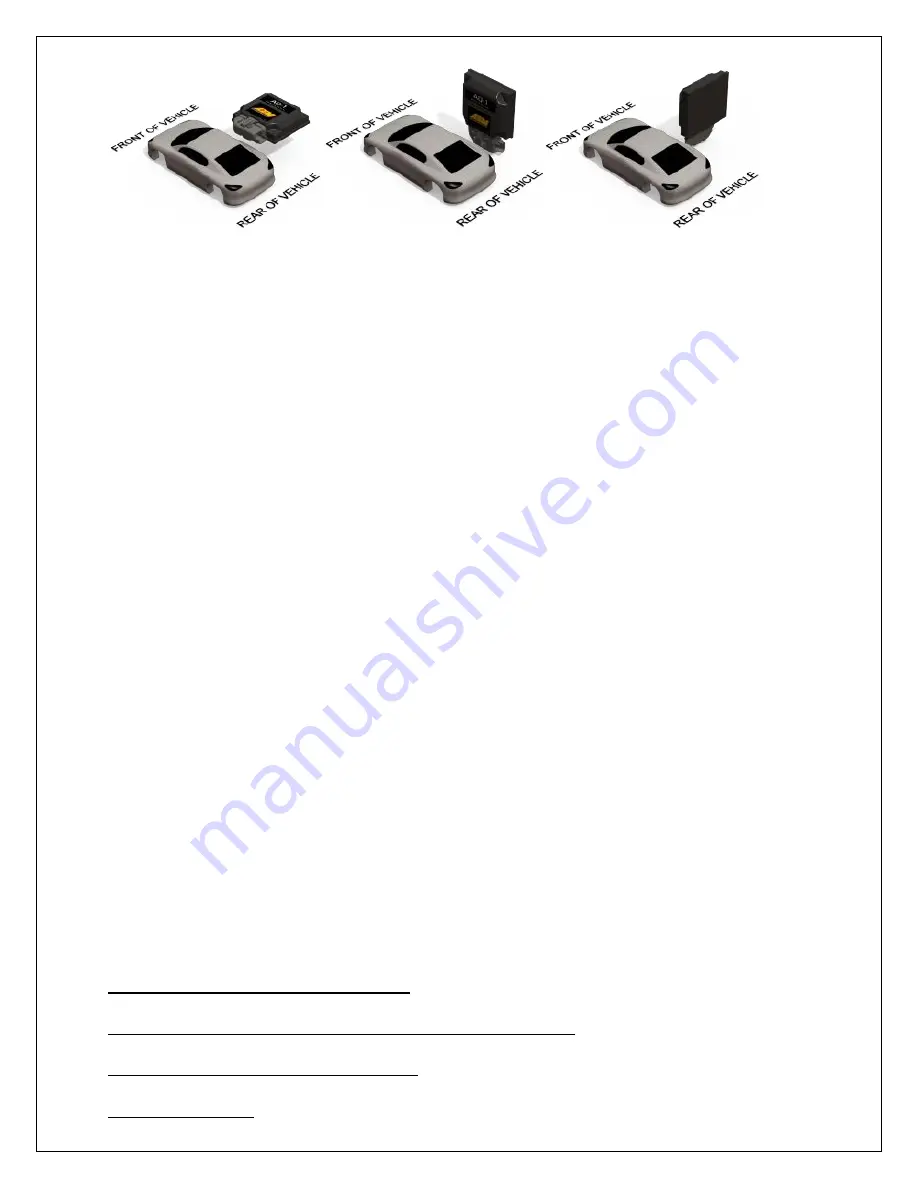

Figure 1. Common Mounting Orientations