20

20

English

Determine why the insertion tool stalled and rectify this, paying

heed to the safety instructions.

Possible causes can be:

• it is tilted in the workpiece to be machined

• breakage of the material to be used

• the power tool is overloaded

Do not reach into the machine while it is running.

The insertion tool may become hot during use.

WARNING! Danger of burns

• when changing tools

• when setting the device down

Chips and splinters must not be removed while the machine is

running.

Always use the protective shields on the machine.

Do not use cracked or distorted saw blades.

Plunge cuts without pre-drilling a hole are possible with soft mate-

rials (wood, light building materials for walls). Harder materials

(metals) must first be drilled with a hole corresponding to the size

of the saw blade.

When working in walls ceiling, or floor, take care to avoid electric

cables and gas or waterpipes.

Always disconnect the plug from the socket before carrying out any

work on the machine.

Do not let any metal parts enter the airing slots - danger of short

circuit!

SPECIFIED CONDITIONS OF USE

This jig saw is intended to cut wood, plastic and metal; it can cut

straight lines, bevels, curves, and internal cut-outs.

MAINS CONNECTION

Connect only to single-phase AC system voltage as indicated on

the rating plate. It is also possible to connect to sockets without an

earthing contact as the design conforms to safety class II.

Appliances used at many different locations including wet room

and open air must be connected via a residual current device (FI,

RCD, PRCD) of 30mA or less.

Only plug-in when machine is switched off.

Keep mains lead clear from working range of the machine. Always

lead the cable away behind you.

MAINTENANCE

The ventilation slots of the machine must be kept clear at all times.

If the replacement of the supply cord is necessary, this has to be

done by the manufacturer or his agent in order to avoid a safety

hazard.

Use only AEG accessories and spare parts. Should components

need to be replaced which have not been described, please contact

one of our AEG service agents (see our list of guarantee/service

addresses).

If needed, an exploded view of the tool can be ordered. Please

state the Article No. as well as the machine type printed on the

label and order the drawing at your local service agents or directly

at Techtronic Industries GmbH, Max-Eyth-Straße 10, 71364 Win-

nenden, Germany.

EC-DECLARATION OF CONFORMITY

We declare under our sole responsibility that the product described

under “Technical Data” fulfills all the relevant provisions of the

directives

2006/42/EC

2011/65/EU (RoHS)

2014/30/EU

and the following harmonized standards have been used.

EN 62841-1:2015

EN 62841-2-11:2016

EN 55014-1:2017+A11:2020

EN 55014-2:2015

EN IEC 61000-3-2:2019

EN 61000-3-3:2013+A1:2019

EN IEC 63000:2018

Winnenden, 2021-10-10

Alexander Krug / Managing Director

Authorized to compile the technical file

Techtronic Industries GmbH

Max-Eyth-Straße 10, 71364 Winnenden, Germany

GB

Summary of Contents for STEP 100

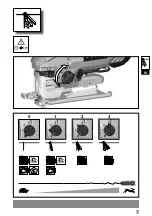

Page 6: ...3 3 I 3 TEST STEP 100 X ...

Page 7: ...4 4 I 1 3 2 TEST STEP 80 STEP 100 ...

Page 8: ...5 5 II 1 2 ...

Page 9: ...6 6 III 1 2 ...

Page 10: ...7 7 IV 0 1 2 3 ...

Page 11: ...8 8 V 1 4 3 2 5 15 0 15 30 45 30 15 0 15 STEP 100 X ...

Page 12: ...9 9 V 1 4 3 2 5 15 0 15 30 45 30 15 0 15 STEP 80 STEP 100 ...

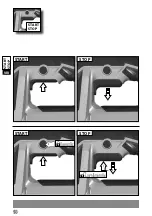

Page 13: ...10 10 VI 1 2 4 3 STEP 100 X ...

Page 14: ...11 11 VI 1 2 4 3 STEP 80 STEP 100 ...

Page 15: ...12 12 VII 1 3 4 5 4 6 6 1 ...

Page 17: ...14 14 VIII START STOP START STOP START START STOP STOP 1 1 2 2 ...

Page 18: ...15 15 IX 2 1 1 1 2 2 1 1 3 A B A AP 2 200 4931 4472 95 B AP 300 4931 4472 94 2 4 5 ...

Page 19: ...16 16 IX ...

Page 20: ...17 17 X 1 2 3 STEP 100 X ...

Page 21: ...18 18 XI 1 2 3 4 STOP START ...