(8)

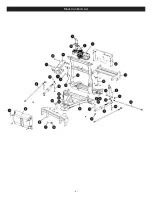

Plow Assembly & Adjustments

Lift Chains

Lift Chains

Attach the Lift Chain to the Lift Arm through the two hooks on the lift

arm. Adjust the lift chain at the lift arm so that there are 2-3 links of slack.

This ensures that the plow blade will lift fully and be able to follow the ground

contour while plowing.

Trip Spring Adjustment

Trip Spring Adjustment

Attach Eye Bolts to Moldboard and Trip Springs to Pivot Bar, making certain

locknuts are positioned as shown below.

Make certain each Eye Bolt is in a vertical position as shown below so that the

Eye Bolt and Trip Spring hinge properly when the Moldboard trips.

Note: Proper tension is attained when the Trip Spring coils just begin to

seperate and then tightening top locknut four additional turns. Tighten

bottom locknut to secure Eye Boilt in positiion.

Install Eye Bolt Caps over exposed threads.

Plow Markers

Plow Markers

Attach Plow Markers to moldboard using 5/16-18 x 1” Bolt, 5/16” Flatwasher,

and 5/16-18 Locknut.

Drop Speed Adjustment

Drop Speed Adjustment

E73 Drop Speed Adjustment: Loosen jam nut and turn knob clockwise to slow

the drop of the plow and counter clockwise to speed the drop of the plow.

Tighten jam nut.

Drop Speed Adjustment

Hydraulic Fluid Level

Hydraulic Fluid Level

Top off the unit to the fill line on the reservoir with Meyer M-1 Hydraulic Fluid.

NOTE: Proper fluid level is to the fill line on the reservoir for the E73. It must be

checked with the lift cylinder fully retracted.

Summary of Contents for MEYER DIAMOND EDGE

Page 3: ...2 Black Iron Parts List...