14

AWS-825B/PB User's Manual

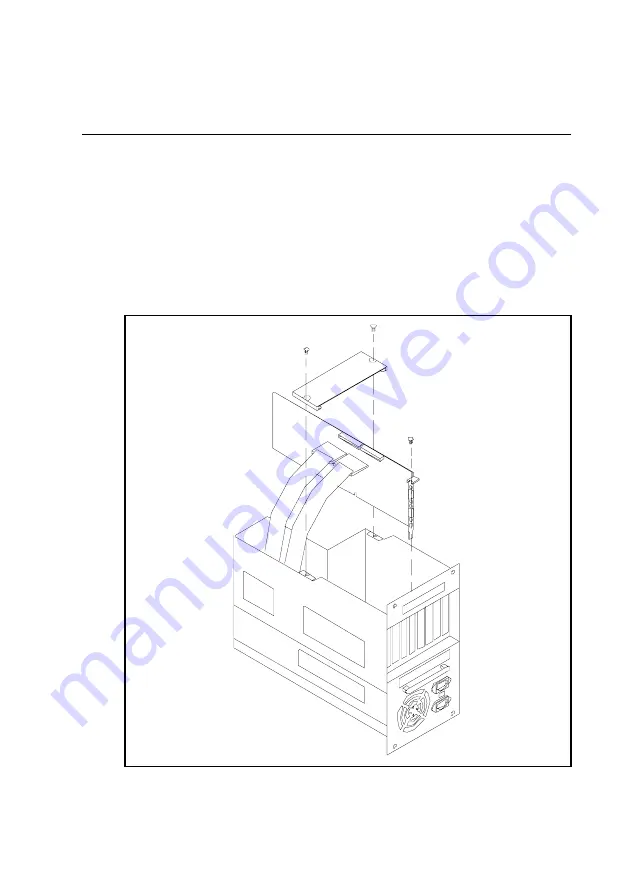

2.3 Adding cards

Remove the cover of the work drawer by either removing the 10

screws that attach it or by sliding it out. Remove the screw that

fixes the card hold-down clamp, and remove the clamp.

Slowly slide the card in and carefully press it into the backplane

socket. Secure it by screwing it into the top mounting bar. (See

Fig. 2-2.) Connect the card wiring. Add any additional cards or

take out cards you need to service. Reattach the hold-down clamp.

When you have finished, reattach the cover.

Figure 2-2: Installing add-on cards

Summary of Contents for AWS-825B

Page 1: ...AWS 825B PB Industrial Workstation with 15 Color CRT Display ...

Page 10: ...x ...

Page 11: ...Introduction Description Specifications Front and rear panel layout Dimensions CHAPTER 1 ...

Page 20: ...10 AWS 825B PB User s Manual ...

Page 23: ...Chapter 2 System Setup 13 Figure 2 1 Detaching the work drawer ...

Page 30: ...20 AWS 825B PB User s Manual ...

Page 35: ...Chapter 3 Maintenance 25 Figure 3 4 Removing the CRT monitor final steps ...

Page 37: ...Chapter 3 Maintenance 27 Figure 3 6 Keyboard translator input output schematic ...

Page 42: ...32 AWS 825B PB User s Manual Figure 3 10 Replacing the membrane keypad ...

Page 44: ...34 AWS 825B PB User s Manual Figure 3 11 Replacing the touchscreen sensor ...

Page 52: ...42 AWS 825B PB User s Manual ...

Page 62: ...52 AWS 825B PB User s Manual ...

Page 63: ...15 Monitor Specifications APPENDIX A ...

Page 66: ...56 AWS 825B PB User s Manual ...

Page 80: ...70 AWS 825B PB User s Manual ...

Page 88: ...78 AWS 825B PB User s Manual a Add M6 behind monmouse in autoexec bat to add drag 15 END ...

Page 94: ...84 AWS 825B PB User s Manual a 9 Test the calibration END ...