Getting Started

Loading Transfer Ribbon

18

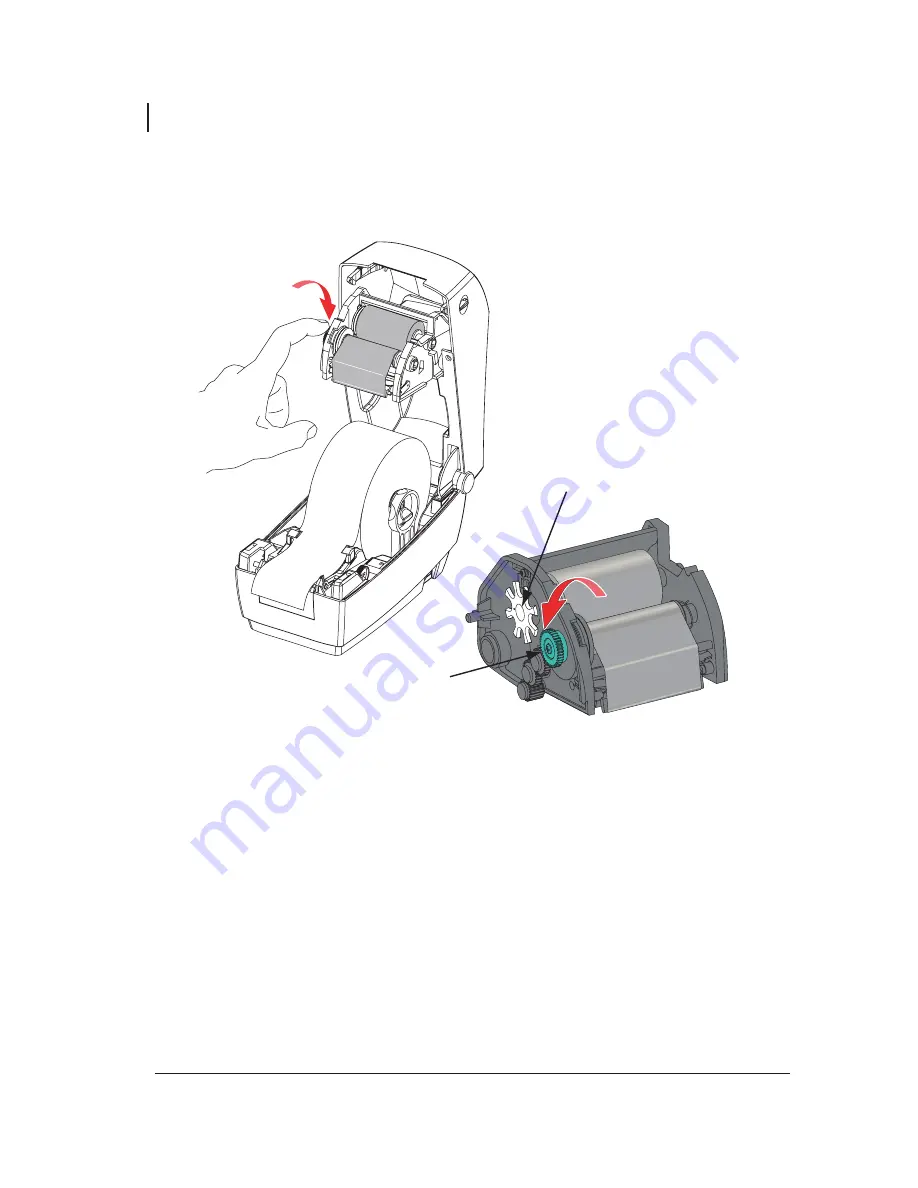

5.

Rotate the thumb wheel on the left side of the ribbon frame by the supply spindle until the

ribbon is pulled tight across the print head.

6.

Verify that the media is loaded and ready to print and then close the printer cover.

7.

Press the Feed button to have the printer feed a minimum of 10 cm (4 inches) of media to

remove slack and ribbon wrinkle, and to align the ribbon on the spindles.

Your printer is now ready to print.

DO NOT TOUCH

Ribbon Out Sensor

Thumb Wheel