Chapter 5 - System Operation

64

Adept Viper s650/s850 Robot with MB-60R User’s Guide, Rev D

6. Repeat steps 4 and 5 above for releasing the brakes on another axis.

NOTE:

When the Status LED (Green) is on, it indicates that the circuit is

enabled, when the Brake Release push button is pressed.

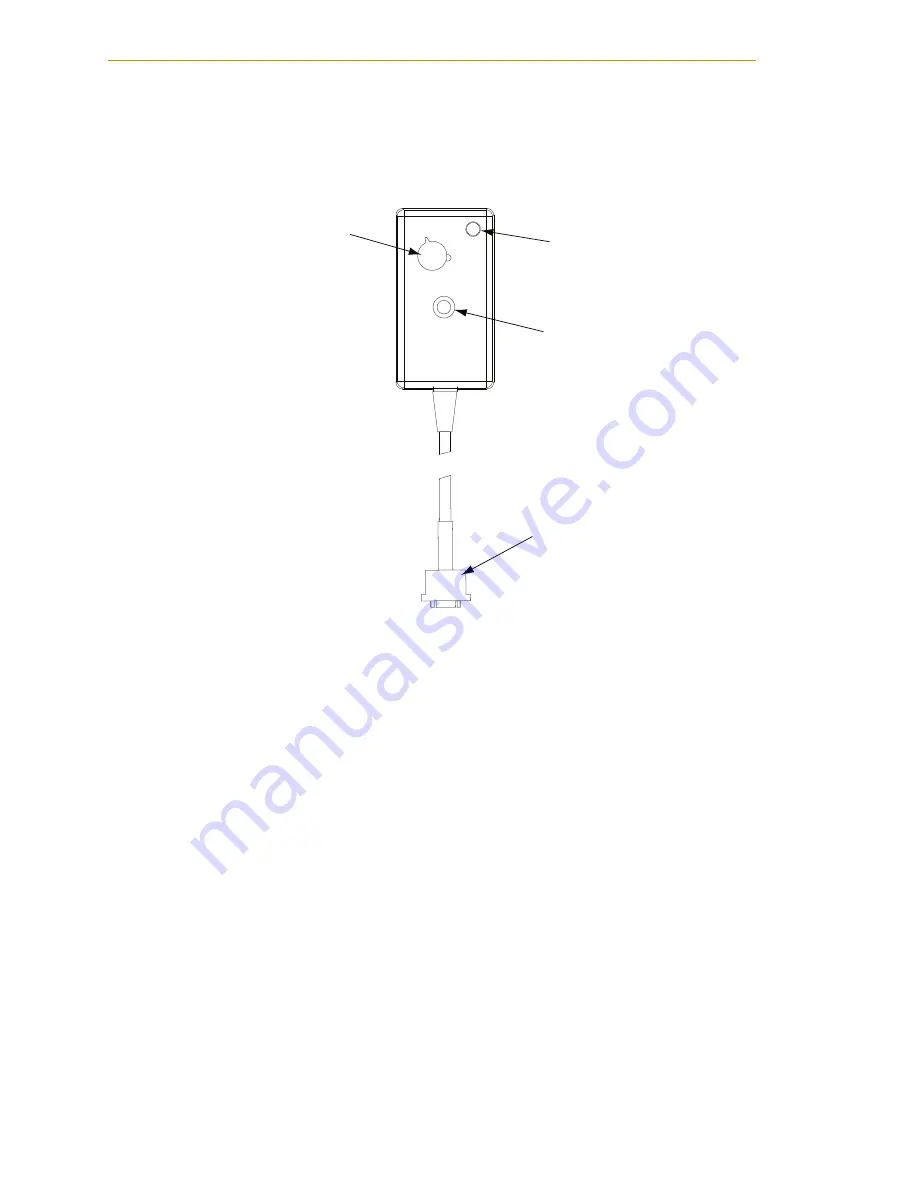

Figure 5-1. Manual Brake-Release Box

Using the Brake Release Switch on UL Robots

This procedure describes how to use the brake release switch on the base of UL robots. See

.

1. Make sure that high power is disabled (off).

2. Press one of the E-Stops (Pendant, Front Panel, or external).

NOTE:

An E-Stop must be activated in order for the brake release to work.

3. Using the axis selector switch, select the axis on which you want to release the

brake.

4. Depress the Brake Release push button, to release the brake.

5. Repeat

and

above to release the brakes on another axis.

NOTE:

When the Status LED (Green) is on, it indicates that the circuit is

enabled, when the Brake Release push button is pressed.

1

2 3 4

5

6

OFF

BRAKE

RELEASE

Axis selector switch

Status LED

Brake Release

Push button

9-pin male

D-Sub connector