Chapter 3: MotionBlox-60R

Adept Viper s650/s850 Robot with MB-60R/eMB-60R User’s Guide, Rev F

Page 36 of 100

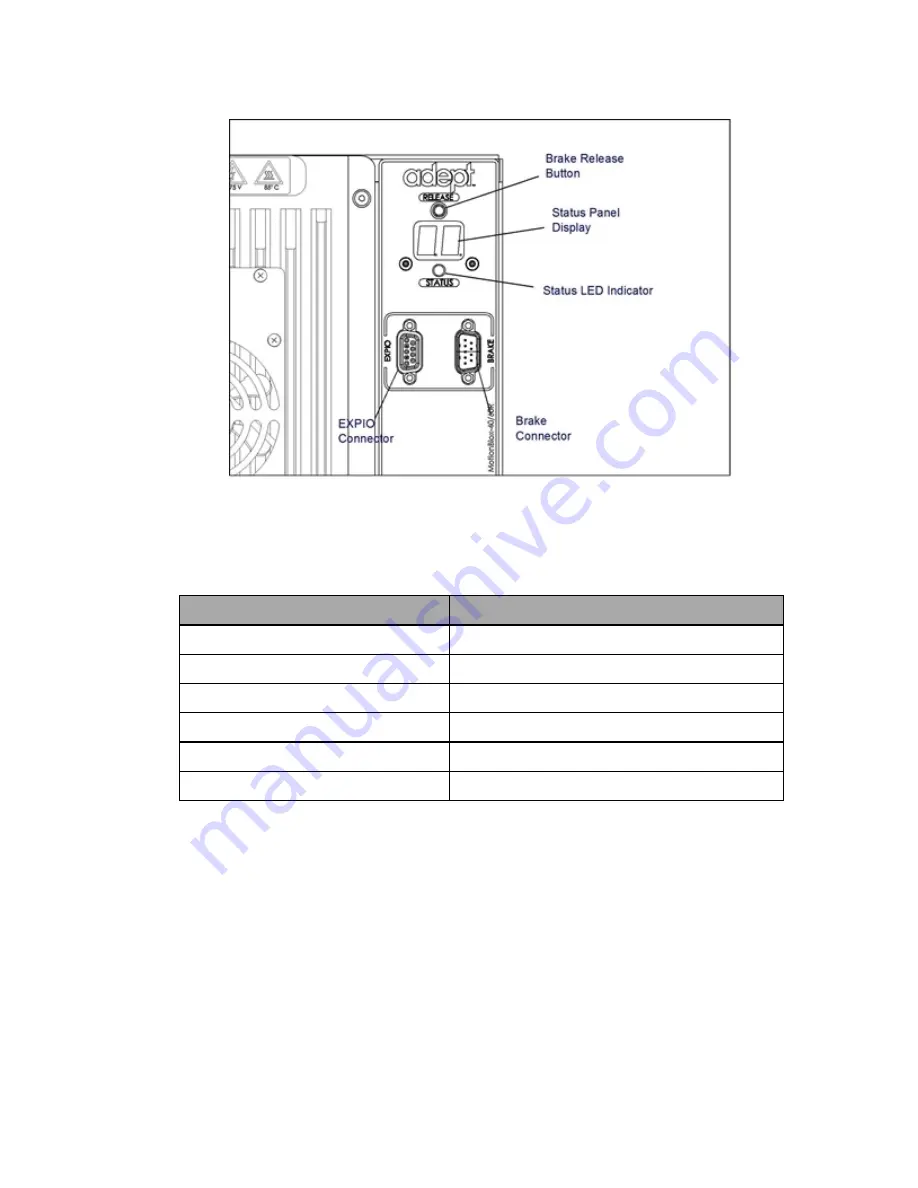

Figure 3-4. Controls and Indicators on MB-60R/eMB-60R

Table 3-2. Status LED Definition

LED Status

Description

Off

24 VDC not present

Green, Slow Blink

High Power Disabled

Green, Fast Blink

High Power Enabled

Green/Red Blink

Selected Configuration Node

Red, Fast Blink

Fault - refer to the following table

Solid Green or Red

Initialization or Robot Fault

Status Panel

The status panel, shown in the preceding figure, displays alpha-numeric codes that indicate

the operating status of the MB-60R/eMB-60R, including detailed fault codes. The following

table gives definitions of the fault codes. These codes provide details for quickly isolating prob-

lems during troubleshooting.

Summary of Contents for eMB-60R

Page 1: ...Adept Viper s650 s850 Robot with MB 60R eMB 60R User s Guide...

Page 2: ......

Page 62: ......

Page 70: ......

Page 82: ......

Page 92: ......

Page 98: ......

Page 99: ......

Page 100: ...P N 05173 060 Rev F 5960 Inglewood Drive Pleasanton CA 94588 925 245 3400...